Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Thermal Spray Wire

Product Details

Our Ni60Cr15 nickel-chromium wire is a rock-solid choice for industrial furnace coatings. This alloy, with 60% nickel, 15% chromium, and a balanced iron content, is built to handle scorching temperatures up to 1150°C while fighting off oxidation and corrosion. It’s perfect for coating furnace components, from burners to heat exchangers, ensuring they stay tough and reliable in the harshest conditions. Available in sizes like 1.6mm and 2.0mm, our wire is designed for thermal spraying, delivering high-bond-strength coatings that stick tight and last long. It’s a cost-effective solution that keeps your furnaces running smoothly without breaking the bank.

The market for furnace coating materials is booming, with projections estimating a $15 billion industry by 2027, growing at a CAGR of 8.2%. Industrial furnaces are the backbone of sectors like power generation, aerospace, and chemical processing, and the demand for durable, high-performance coatings is skyrocketing. Companies are leaning into automation for faster, more consistent coating applications and prioritizing eco-friendly materials to meet stricter environmental regulations. Our Ni60Cr15 wire fits right into this trend, offering a balance of performance and affordability that’s hard to beat in high-temperature environments.

| Nickel (Ni) | 95% |

| Aluminum (Al) | 5% |

| Melting Point | 1400-1450°C |

| Density | 8.9 g/cm³ |

| Bond Strength | ≥ 55 MPa (Flame spray), ≥ 70 MPa (Electric arc spray) |

| Size | 1.2/1.6/2.0mm |

| Weight of Axle | 15kg |

| Parameter | Recommended Value |

| Spray Voltage | 30-40V |

| Spray Current | 100-300A |

| Air Pressure | 0.4-0.6MPa |

| Spray Distance | 100-150mm |

| Preheat Temperature | 80-150°C |

| Coating Thickness | 0.1-1.5mm |

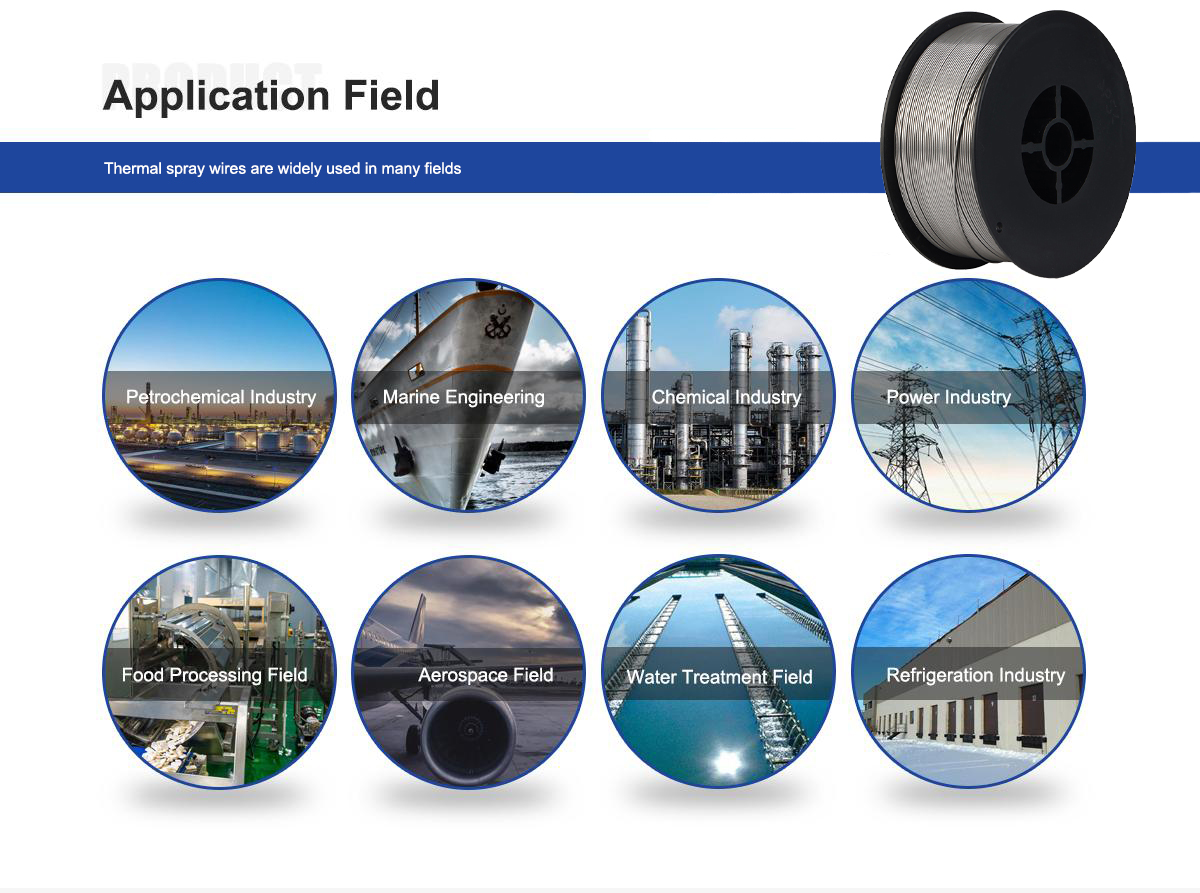

Our Ni60Cr15 nickel-chromium wire is a go-to for protecting furnace components across multiple industries:

Power Generation: Coats boiler tubes and heat exchangers to withstand intense heat and corrosive gases.

Aerospace: Protects furnace parts used in jet engine manufacturing from thermal stress and oxidation.

Chemical Processing: Shields reactors and furnace linings from acidic and corrosive environments.

Industrial Manufacturing: Enhances furnace rollers and molds for consistent performance in high-heat settings.

It’s also great for repairing worn furnace parts or adding protective layers to boost longevity. If your furnace faces extreme heat or harsh conditions, our wire is your solution.

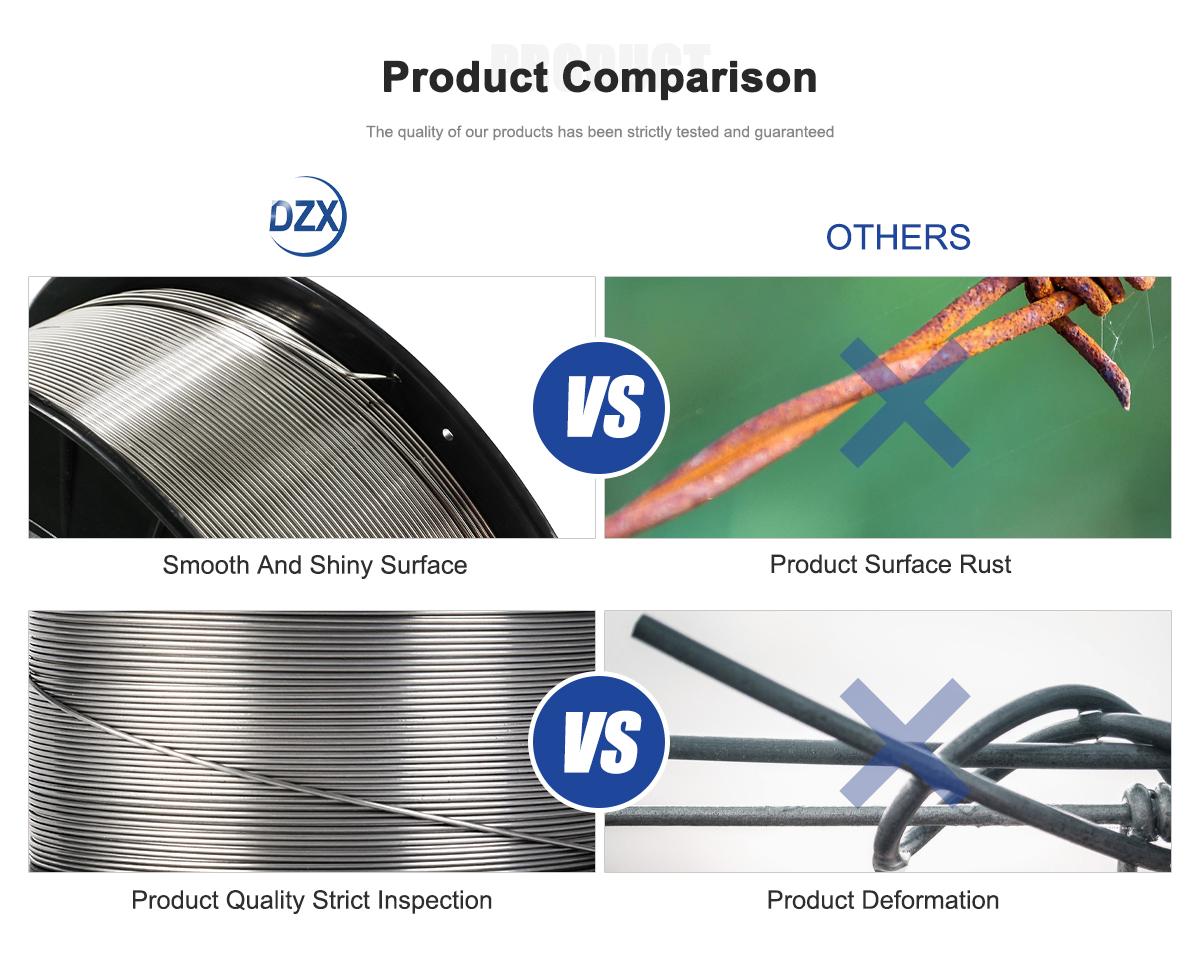

Our Ni60Cr15 wire stands out in the market because we prioritize quality and value. We use high-purity alloys to ensure consistent, reliable coatings with bond strengths over 8500 psi and minimal porosity. This means longer-lasting protection and fewer maintenance headaches for you. We offer flexible wire sizes and fast delivery to keep your operations on track, plus expert support to fine-tune your coating process. Unlike others, we deliver high performance at a price that makes sense, making our wire a smart choice for any furnace application. With us, you’re getting a product and a partner dedicated to your success.

Parameter | Ni60Cr15 Nickel-Chromium Wire | Other Coating Wires |

|---|---|---|

Composition | 60% Ni, 15% Cr, Fe balance | Varies (e.g., Ni80Cr20, FeCrAl) |

Max Operating Temperature | Up to 1150°C | Up to 1100-1200°C |

Oxidation Resistance | Very Good | Good to Excellent |

Bond Strength | >8500 psi | 7000-9000 psi |

Corrosion Resistance | Good, especially in acids | Moderate to High |

Machinability | Good | Moderate to Good |

Coating Density | High, low porosity | Moderate to High |

Cost Efficiency | High, cost-effective | Varies, often higher |

Our Ni60Cr15 wire is your ticket to durable, cost-effective furnace coatings. It’s tough enough for extreme heat, corrosion, and wear, yet affordable enough to keep your budget in check. Want to keep your furnaces running strong and efficient? Contact us today for a quote or to learn how our wire can make your operations shine.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is Ni60Cr15 nickel-chromium wire made of?

It’s a nickel-chromium alloy with 60% nickel, 15% chromium, and iron balance, optimized for high-temperature and corrosion resistance.

What industries rely on Ni60Cr15 wire?

It’s used in industrial furnaces, power generation, aerospace, and chemical processing for protective coatings.

What are the primary applications of Ni60Cr15 wire?

It’s applied to furnace components to protect against heat, oxidation, and corrosive gases, extending equipment life.

How does Ni60Cr15 compare to other furnace coating materials?

It offers excellent heat resistance up to 1150°C, good corrosion resistance, and affordability compared to higher-nickel alloys.

What benefits does Ni60Cr15 wire provide for furnace coatings?

It delivers durable, heat-resistant coatings, reduces maintenance costs, and enhances furnace performance in extreme conditions.

What are the latest trends in industrial furnace coatings?

The industry is shifting toward automated thermal spraying and sustainable materials to improve efficiency and reduce environmental impact.

How is Ni60Cr15 wire applied to furnace components?

It’s typically applied via thermal spraying, creating a dense, protective coating that bonds tightly to metal surfaces.

Why choose Ni60Cr15 for industrial furnace coatings?

Its balance of heat resistance, corrosion protection, and cost-effectiveness makes it ideal for high-temperature furnace environments.