Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Thermal Spray Wire

Product Details

Our 45CT Thermal Spray Wire is a heavy-duty solution for protecting boiler superheaters. This nickel-chromium-titanium alloy, with around 45% chromium and a touch of titanium, is built to take on extreme heat and nasty corrosive environments. It can handle temperatures up to 1200°C and thrives in high-sulfur conditions, making it perfect for power plants and petrochemical facilities. Applied through arc or plasma spraying, it creates a rock-solid, high-bond-strength coating that sticks like glue and keeps your superheaters safe from erosion and oxidation. Available in sizes like 1.6mm and 2.0mm, it’s easy to use and delivers long-lasting protection.

The thermal spray market for boiler applications is growing fast, with estimates pegging it at $8 billion by 2028, driven by a CAGR of 7.5%. Power generation and petrochemical industries are pushing for coatings that can handle tougher conditions while meeting strict environmental regulations. Automated spraying systems are gaining traction for their precision and efficiency, and there’s a big focus on sustainable materials that reduce waste. Our 45CT wire is right in the sweet spot, offering top-tier performance in high-heat, high-corrosion settings without the premium price tag of some alternatives.

| Nickel (Ni) | 95% |

| Aluminum (Al) | 5% |

| Melting Point | 1400-1450°C |

| Density | 8.9 g/cm³ |

| Bond Strength | ≥ 55 MPa (Flame spray), ≥ 70 MPa (Electric arc spray) |

| Size | 1.2/1.6/2.0mm |

| Weight of Axle | 15kg |

| Parameter | Recommended Value |

| Spray Voltage | 30-40V |

| Spray Current | 100-300A |

| Air Pressure | 0.4-0.6MPa |

| Spray Distance | 100-150mm |

| Preheat Temperature | 80-150°C |

| Coating Thickness | 0.1-1.5mm |

Our 45CT thermal spray wire is a go-to for protecting boiler superheaters and related components:

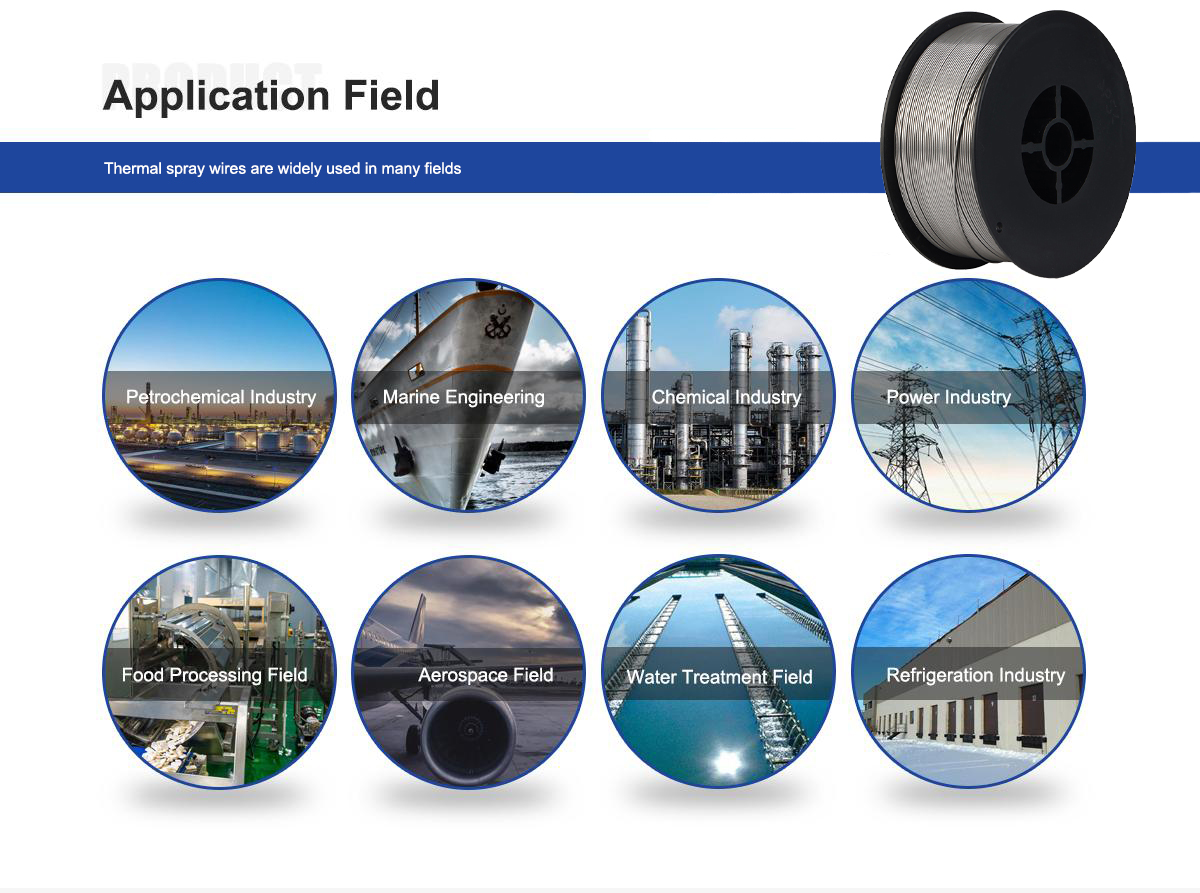

Power Generation: Coats superheater tubes to resist heat, corrosion, and erosion in coal or gas-fired boilers.

Petrochemical: Shields furnace tubes and reactors from high-sulfur and acidic environments.

Industrial Boilers: Protects critical components in high-temperature manufacturing processes.

Maintenance and Repair: Restores worn superheater surfaces, extending equipment life.

It’s also great for creating protective barriers in environments with aggressive gases or extreme thermal cycling. If your boilers face tough conditions, our wire is your answer.

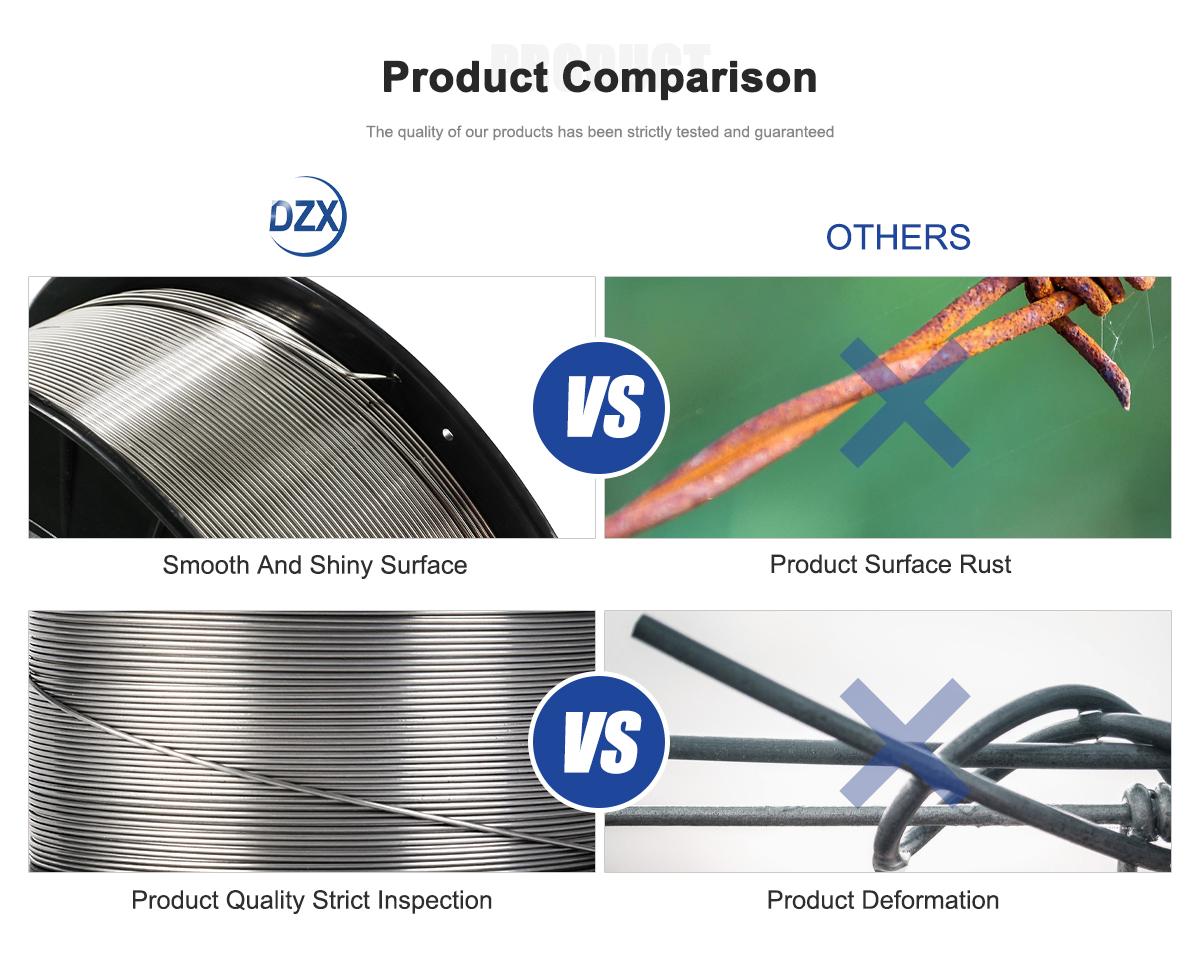

Our 45CT wire sets the bar high. We use high-purity alloys to ensure consistent, top-notch coatings with bond strengths over 9500 psi and super-low porosity. This means your superheaters stay protected longer, saving you on repairs and downtime. We offer flexible sizing, fast shipping, and hands-on support to optimize your spraying process. Unlike others, we balance premium performance with affordability, giving you a cost-effective solution for even the harshest environments. With us, you’re not just buying wire—you’re getting a partner committed to keeping your boilers running strong.

Parameter | 45CT Thermal Spray Wire | Other Thermal Spray Wires |

|---|---|---|

Composition | Ni, ~45% Cr, Ti | Varies (e.g., NiCr, FeCrAl) |

Max Operating Temperature | Up to 1200°C | Up to 1100-1150°C |

Oxidation Resistance | Excellent | Good to Very Good |

Bond Strength | >9500 psi | 7000-9000 psi |

Corrosion Resistance | Superior in high-sulfur | Moderate to Good |

Machinability | Good | Moderate to Good |

Coating Density | Very High, low porosity | Moderate to High |

Cost Efficiency | Competitive, long-term savings | Varies, often higher |

Our 45CT wire is your key to long-term boiler superheater protection. It’s tough, reliable, and built to handle extreme heat and corrosion, all while keeping costs in check. Ready to boost your boiler performance and cut maintenance headaches? Contact us today for a quote or to learn how our wire can keep your operations firing on all cylinders.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is 45CT thermal spray wire made of?

It’s a nickel-chromium-titanium alloy with roughly 45% chromium and titanium for exceptional corrosion and heat resistance.

What industries use 45CT thermal spray wire?

It’s used in power generation, petrochemical, and industrial boiler systems for superheater and component protection.

What are the main applications of 45CT wire?

It’s applied to boiler superheaters and tubes to shield against high-temperature corrosion, erosion, and oxidation.

How does 45CT compare to other thermal spray wires?

It offers superior corrosion resistance in high-sulfur environments and maintains stability up to 1200°C, outperforming standard alloys.

What benefits does 45CT wire provide for boiler superheaters?

It extends equipment life, reduces downtime, and protects against harsh conditions, lowering maintenance costs.

What are the latest trends in boiler superheater coatings?

The industry is adopting automated spraying and eco-friendly materials to improve efficiency and meet environmental standards.

How is 45CT thermal spray wire applied?

It’s applied via arc or plasma spraying, forming a dense, high-bond-strength coating on superheater surfaces.

Why choose 45CT for boiler superheater protection?

Its high chromium and titanium content ensures unmatched protection in extreme heat and corrosive environments.