Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Thermal Spray Wire

Product Details

Our Ni80Cr20 nichrome wire is a rockstar for high-temperature oxidation resistance. This alloy, with 80% nickel and 20% chromium, is built to take on scorching heat up to 1200°C while keeping oxidation and corrosion at bay. It’s the go-to choice for coating parts in industrial furnaces, aerospace engines, and power generation systems. Using thermal spraying, our wire creates a tough, high-bond-strength coating that sticks like glue and keeps your components running strong. Available in sizes like 1.2mm, 1.6mm, and 2.0mm, it’s versatile and easy to work with for any high-heat job.

The market for high-temperature coatings is sizzling, expected to hit $11 billion by 2027 with a CAGR of 8.3%. Industries like aerospace, power generation, and chemical processing are driving demand for materials that can handle extreme heat and harsh conditions. There’s a big push for automated spraying systems to boost precision and efficiency, plus a focus on eco-friendly coatings to meet tougher environmental regulations. Our Ni80Cr20 wire is perfectly positioned, offering top-notch performance and durability that industries need to keep equipment running longer and stronger.

| Nickel (Ni) | 95% |

| Aluminum (Al) | 5% |

| Melting Point | 1400-1450°C |

| Density | 8.9 g/cm³ |

| Bond Strength | ≥ 55 MPa (Flame spray), ≥ 70 MPa (Electric arc spray) |

| Size | 1.2/1.6/2.0mm |

| Weight of Axle | 15kg |

| Parameter | Recommended Value |

| Spray Voltage | 30-40V |

| Spray Current | 100-300A |

| Air Pressure | 0.4-0.6MPa |

| Spray Distance | 100-150mm |

| Preheat Temperature | 80-150°C |

| Coating Thickness | 0.1-1.5mm |

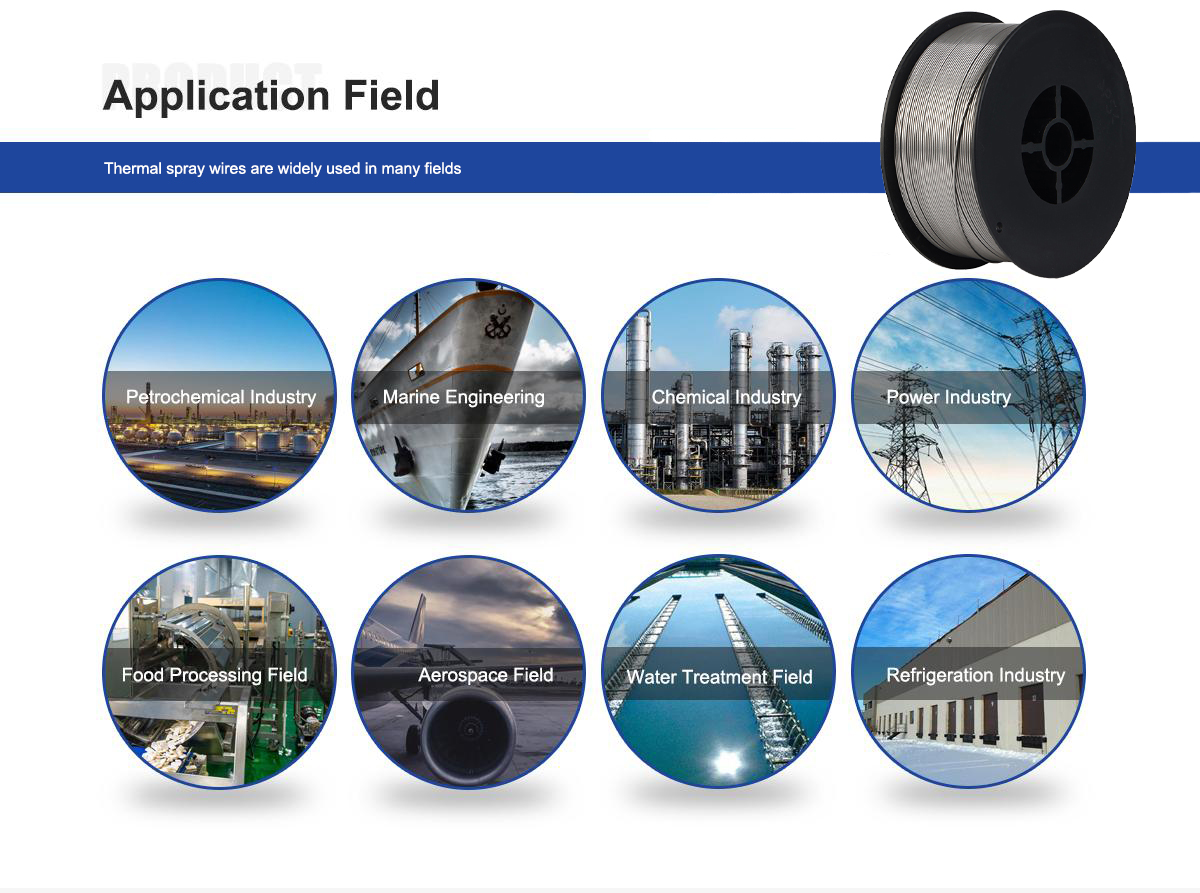

Our Ni80Cr20 nichrome wire shines in high-temperature environments across multiple sectors:

Aerospace: Coats turbine blades and engine parts to resist heat and oxidation.

Power Generation: Protects boiler tubes and heat exchangers from high-temperature wear.

Industrial Furnaces: Shields furnace components from oxidation and thermal stress.

Chemical Processing: Coats reactors and pipes to withstand corrosive, high-heat conditions.

It’s also perfect for restoring worn parts or adding protective layers to extend service life. If your equipment faces extreme heat, our wire is your solution.

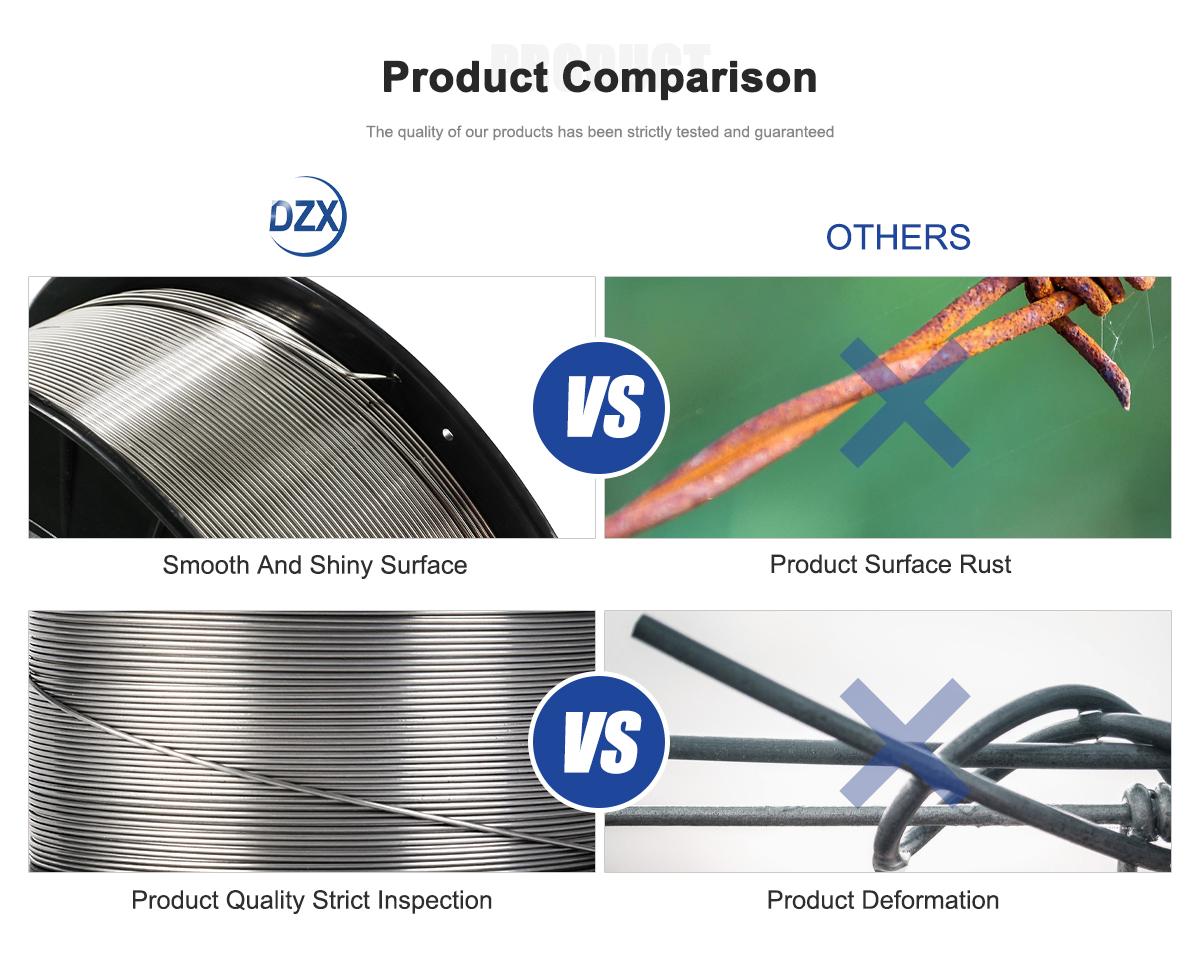

Our Ni80Cr20 wire stands out because we’re all about quality and reliability. We use high-purity alloys to deliver consistent, high-performance coatings with bond strengths over 9000 psi and minimal porosity. This means longer-lasting protection and fewer maintenance headaches. We offer flexible sizing, fast delivery, and expert guidance to optimize your coating process. Unlike others, we balance premium performance with cost-effectiveness, making our wire a smart choice for high-temperature applications. With us, you’re getting a dependable product and a partner dedicated to keeping your operations running smoothly.

Parameter | Ni80Cr20 Nichrome Wire | Other High-Temperature Wires |

|---|---|---|

Composition | 80% Ni, 20% Cr | Varies (e.g., Ni60Cr15, FeCrAl) |

Max Operating Temperature | Up to 1200°C | Up to 1100-1150°C |

Oxidation Resistance | Outstanding | Good to Very Good |

Bond Strength | >9000 psi | 7000-8500 psi |

Corrosion Resistance | Excellent, especially in acids | Moderate to Good |

Machinability | Excellent | Moderate to Good |

Coating Density | Very High, low porosity | Moderate to High |

Cost Efficiency | Competitive, long-term savings | Varies, often higher |

Our Ni80Cr20 wire is your answer for unbeatable high-temperature oxidation resistance. It’s tough, reliable, and built to handle the harshest conditions while keeping costs in check. Ready to protect your components and boost performance? Contact us today for a quote or to learn how our wire can keep your operations firing on all cylinders.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is Ni80Cr20 nichrome wire made of?

It’s a nickel-chromium alloy with 80% nickel and 20% chromium, engineered for superior heat and oxidation resistance.

What industries use Ni80Cr20 nichrome wire?

It’s used in aerospace, power generation, industrial furnaces, and chemical processing for high-temperature applications.

What are the main applications of Ni80Cr20 wire?

It’s used for coating components to protect against oxidation, corrosion, and wear in extreme heat environments.

How does Ni80Cr20 compare to other high-temperature wires?

It offers exceptional oxidation resistance up to 1200°C, high bond strength, and better durability than lower-nickel alloys.

What benefits does Ni80Cr20 wire provide for high-temperature coatings?

It extends component life, reduces maintenance, and ensures performance in harsh, high-heat conditions.

What are the latest trends in high-temperature wire coatings?

The industry is adopting automated spraying systems and eco-friendly materials for improved efficiency and sustainability.

How is Ni80Cr20 nichrome wire applied?

It’s applied via thermal spraying, creating a dense, protective coating with excellent adhesion to metal surfaces.

Why choose Ni80Cr20 for high-temperature oxidation resistance?

Its high nickel content and heat stability make it ideal for protecting components in extreme thermal environments.