Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Thermal Spray Wire

Product Details

Our Ni95Al5 Thermal Spray Wire is a game-changer for industries needing tough, reliable coatings. Made from a nickel-aluminum alloy (95% nickel, 5% aluminum), this wire is designed for arc and flame spray systems, delivering dense, high-strength bond coatings that stick like glue to most metal surfaces. The secret? An exothermic reaction during spraying creates coatings with bond strengths over 9000 psi, ensuring durability even in harsh environments. Whether you’re protecting turbine blades, restoring worn parts, or boosting corrosion resistance, our Ni95Al5 wire gets the job done. Available in standard sizes like 1.6mm and 2.0mm, we also customize to fit your specific needs.

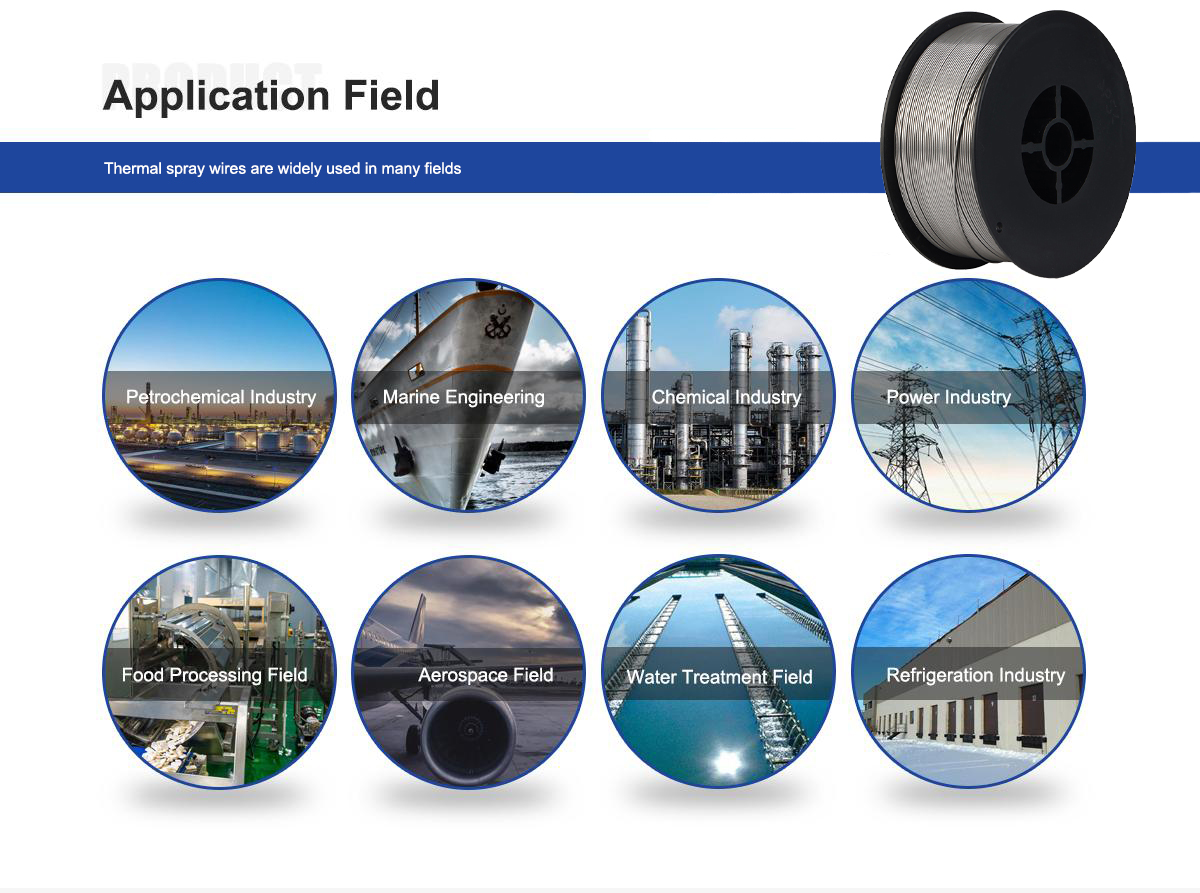

The thermal spray coatings market is booming, projected to hit USD 40.57 billion by 2032 with a 7.5% CAGR (Data Bridge Market Research). Why? Industries like aerospace, automotive, and energy are demanding coatings that extend component life under extreme conditions. Ni95Al5 wire is a star player here, thanks to its ability to form strong, low-porosity coatings that resist oxidation and wear. The push for eco-friendly, lead-free coatings is also driving demand for aluminum-based alloys like ours, especially in regions like Asia-Pacific, where manufacturing hubs in China and India are ramping up production. Technological advancements, like improved spray systems and automation, are making coatings more precise and efficient, further fueling market growth.

| Nickel (Ni) | 95% |

| Aluminum (Al) | 5% |

| Melting Point | 1400-1450°C |

| Density | 8.9 g/cm³ |

| Bond Strength | ≥ 55 MPa (Flame spray), ≥ 70 MPa (Electric arc spray) |

| Size | 1.2/1.6/2.0mm |

| Weight of Axle | 15kg |

| Parameter | Recommended Value |

| Spray Voltage | 30-40V |

| Spray Current | 100-300A |

| Air Pressure | 0.4-0.6MPa |

| Spray Distance | 100-150mm |

| Preheat Temperature | 80-150°C |

| Coating Thickness | 0.1-1.5mm |

Our Ni95Al5 wire shines in a range of applications:

Aerospace: Protects turbine blades and engine components from high-temperature oxidation and wear.

Automotive: Enhances exhaust systems and pistons for better corrosion resistance and longevity.

Energy: Shields wind turbines and oil rig parts from harsh environments.

Glass Industry: Coats moulds to resist heat and scaling, ensuring smooth production.

Dimensional Restoration: Repairs worn parts like crankshafts and cylinder blocks, saving costs on replacements.

Its versatility makes it a go-to for both bond coats and standalone coatings, delivering performance where it counts.

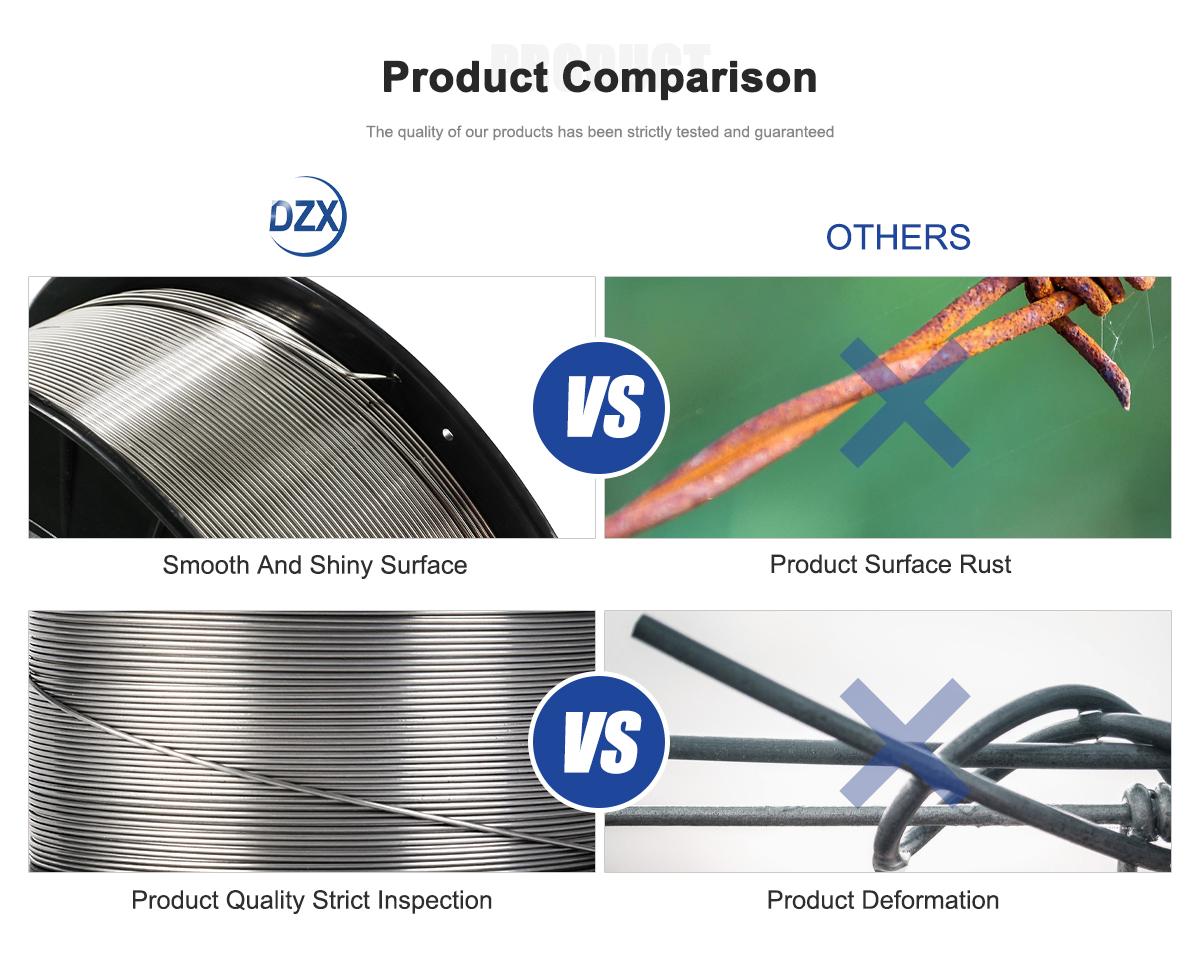

Compared to other suppliers, our Ni95Al5 wire stands out for its consistent quality and performance. We’ve fine-tuned our manufacturing to ensure stable chemical composition and low oxygen content, resulting in coatings with exceptional bond strength and durability. While others may offer similar alloys, our wire’s high purity and optimized exothermic reaction deliver denser coatings with less porosity. We also provide flexible sizing and packaging, tailored to your project’s needs. Our ISO-certified processes guarantee reliability, and our focus on R&D keeps us ahead of industry trends, ensuring you get cutting-edge solutions for your coating challenges.

Parameter | Ni95Al5 Thermal Spray Wire | Other Thermal Spray Wires |

|---|---|---|

Composition | 95% Nickel, 5% Aluminum | Varies (e.g., Fe-based, NiCr) |

Bond Strength | >9000 psi | 5000–8000 psi |

Oxidation Resistance | Excellent (up to 1200°C) | Moderate to good |

Coating Density | High, low porosity | Moderate to high porosity |

Application Method | Arc spray, flame spray | Arc, flame, HVOF, plasma |

High-Temperature Use | Ideal for extreme conditions | Varies, often less stable |

Corrosion Resistance | Excellent | Good, depends on alloy |

Typical Layer Thickness | 0.1–0.15 mm | 0.05–0.2 mm |

Our Ni95Al5 thermal spray wire is your ticket to high-performance coatings that last. With unmatched bond strength, excellent resistance to heat and corrosion, and versatility across industries, it’s a smart choice for protecting and restoring critical components. As the thermal spray market grows, we’re committed to delivering top-tier products that meet your needs and keep you ahead of the curve.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is Ni95Al5 thermal spray wire?

It’s a nickel-aluminum alloy wire (95% nickel, 5% aluminum) used in thermal spraying to create strong, durable bond coatings with excellent adhesion.

What are the main applications of Ni95Al5 wire?

It’s used for bond coatings, dimensional restoration, high-temperature corrosion resistance, and wear protection in industries like aerospace, automotive, and glass manufacturing.

Why choose Ni95Al5 for bond coatings?

Its exothermic reaction during spraying ensures dense coatings with bond strengths exceeding 9000 psi, sticking well to most metallic substrates.

How does Ni95Al5 perform in high-temperature environments?

It offers excellent oxidation and heat shock resistance, making it ideal for components exposed to extreme temperatures.

What are the typical wire sizes for Ni95Al5?

Common sizes are 1.6mm and 2.0mm, but we can customize sizes based on your needs.

Can Ni95Al5 be used as a standalone coating?

Yes, it can serve as a working layer due to its dense structure and resistance to abrasion and corrosion.

What industries benefit most from Ni95Al5 coatings?

Aerospace, automotive, energy, and glass industries rely on it for durable, high-performance coatings.

How does Ni95Al5 compare to other thermal spray materials?

It provides superior bond strength, low porosity, and high-temperature resistance compared to many alternatives, making it a top choice for demanding applications.

Previous article:Ni95Al5 Wire for Wear-Resistant Turbine Blade Coatings

Next article:Ni95Al5 Nickel Alloy Wire for Glass Mold Thermal Spray Coatings