Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Thermal Spray Wire

Product Details

Our Ni95Al5 nickel alloy wire is a powerhouse for glass mold coatings. This 95% nickel, 5% aluminum alloy is engineered for thermal spray systems, creating tough, high-strength coatings that stick tightly to surfaces. Its exothermic reaction during spraying ensures bond strengths above 9000 psi, making it a go-to for glass molds that face intense heat and wear. Available in 1.6mm and 2.0mm sizes, or customized to your needs, this wire delivers reliable, long-lasting protection for critical components in glass manufacturing and beyond.

The thermal spray coatings market is on fire, expected to reach USD 40.57 billion by 2032 with a 7.5% CAGR (Data Bridge Market Research). Glass manufacturing is a big driver, as producers demand coatings that extend mold life and improve production efficiency. Ni95Al5 wire fits perfectly here, offering low-porosity coatings that resist scaling and thermal shock. The shift toward sustainable, lead-free coatings is boosting demand for nickel-aluminum alloys, especially in Asia-Pacific, where glass production is surging in countries like China and India. Advances in spray technology, like automated systems, are also making coatings more consistent and cost-effective, pushing market growth.

| Nickel (Ni) | 95% |

| Aluminum (Al) | 5% |

| Melting Point | 1400-1450°C |

| Density | 8.9 g/cm³ |

| Bond Strength | ≥ 55 MPa (Flame spray), ≥ 70 MPa (Electric arc spray) |

| Size | 1.2/1.6/2.0mm |

| Weight of Axle | 15kg |

| Parameter | Recommended Value |

| Spray Voltage | 30-40V |

| Spray Current | 100-300A |

| Air Pressure | 0.4-0.6MPa |

| Spray Distance | 100-150mm |

| Preheat Temperature | 80-150°C |

| Coating Thickness | 0.1-1.5mm |

Our Ni95Al5 wire is a versatile performer, with key applications including:

Glass Manufacturing: Coats molds to resist high temperatures, scaling, and wear, ensuring smooth production and longer mold life.

Aerospace: Protects turbine blades and engine parts from oxidation and thermal stress.

Automotive: Enhances components like exhaust systems for better corrosion resistance.

Energy: Shields wind turbine parts and oil rig equipment from harsh conditions.

Surface Restoration: Repairs worn parts like shafts or rollers, cutting replacement costs.

Its ability to serve as both a bond coat and a standalone layer makes it a flexible solution for demanding environments.

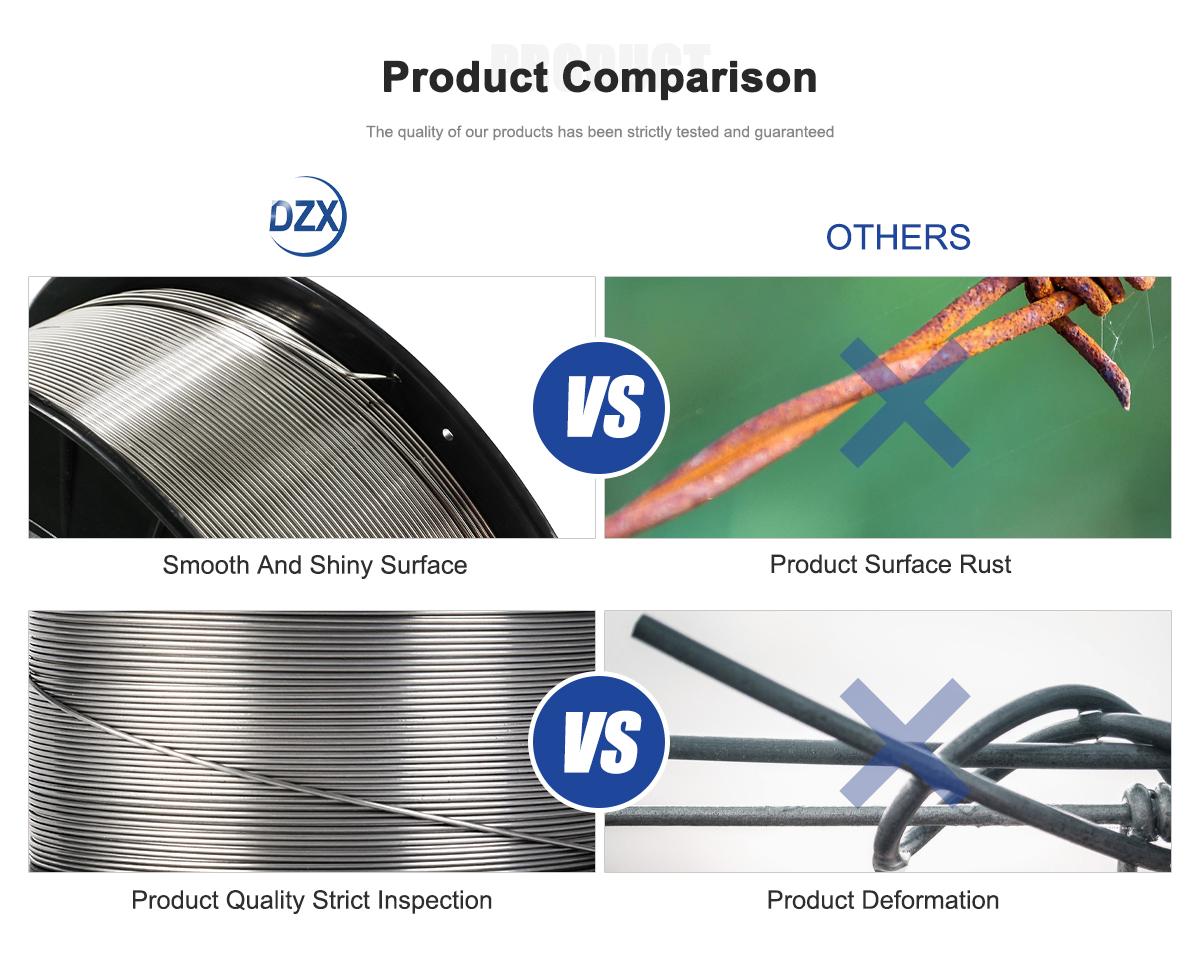

Our Ni95Al5 wire sets the bar high. We prioritize purity and precision in manufacturing, ensuring consistent composition and low oxygen content for coatings with unbeatable bond strength and minimal porosity. While others may offer similar alloys, our wire’s optimized exothermic reaction delivers denser, more durable coatings. We offer flexible sizing and packaging to fit your project, backed by ISO-certified processes for reliability. Our focus on R&D keeps us ahead, providing cutting-edge solutions tailored to the glass industry and beyond.

Parameter | Ni95Al5 Nickel Alloy Wire | Other Coating Wires |

|---|---|---|

Composition | 95% Nickel, 5% Aluminum | Varies (e.g., NiCr, Fe-based) |

Bond Strength | >9000 psi | 6000–8500 psi |

Oxidation Resistance | Excellent (up to 1200°C) | Moderate to good |

Coating Density | High, low porosity | Moderate to high porosity |

Application Method | Arc spray, flame spray | Arc, flame, HVOF, plasma |

Thermal Shock Resistance | Superior | Varies, often lower |

Corrosion Resistance | Excellent | Good, depends on alloy |

Typical Layer Thickness | 0.1–0.15 mm | 0.05–0.2 mm |

Our Ni95Al5 nickel alloy wire is a top-tier choice for glass mold coatings and more. With exceptional bond strength, heat resistance, and versatility, it’s built to handle the toughest challenges in glass manufacturing, aerospace, and energy. As the thermal spray market grows, we’re committed to delivering high-quality, innovative products that keep your operations running smoothly and efficiently.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is Ni95Al5 nickel alloy wire?

It’s a high-purity nickel-aluminum alloy wire (95% nickel, 5% aluminum) used in thermal spraying to create robust coatings for glass molds.

What are the key applications of Ni95Al5 wire?

It’s primarily used for glass mold coatings, corrosion protection, and surface restoration in industries like glass manufacturing, aerospace, and energy.

Why is Ni95Al5 ideal for glass mold coatings?

Its exothermic reaction during spraying forms dense coatings with bond strengths over 9000 psi, perfect for withstanding high temperatures and wear.

How does Ni95Al5 handle high-temperature environments?

It offers excellent resistance to oxidation and thermal shock, ensuring glass molds perform reliably under extreme heat.

What wire sizes are available for Ni95Al5?

Standard sizes include 1.6mm and 2.0mm, with custom sizes available to match your specific requirements.

Can Ni95Al5 be used beyond glass molds?

Yes, it works as a bond coat or standalone coating for parts needing corrosion and wear resistance, like turbine blades or automotive components.

Which industries benefit from Ni95Al5 coatings?

Glass manufacturing, aerospace, automotive, and energy sectors rely on its durability and high-performance coatings.

How does Ni95Al5 compare to other coating materials?

It delivers superior bond strength, low porosity, and excellent heat resistance, making it a top pick for demanding glass mold applications.

Previous article:Ni95Al5 Thermal Spray Wire for High-Strength Bond Coatings

Next article:Ni80Cr20 Wire for Electric Heating Element Surface Protection