Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nickel Welding Wire

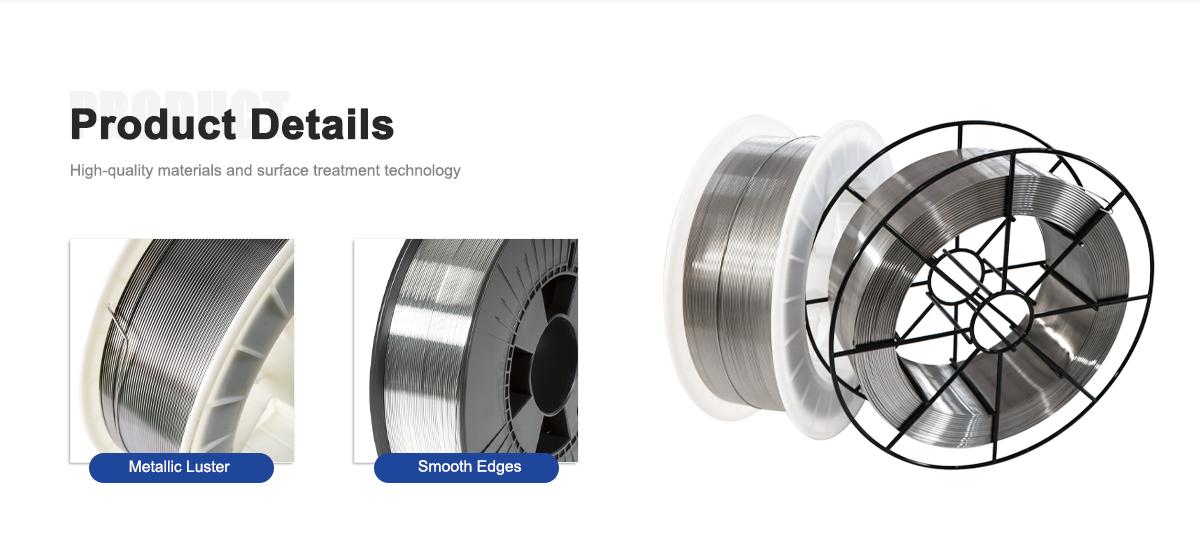

Product Details

We’re proud to offer our ERNiCrMo-4 Hastelloy C276 welding rod, a top-tier solution for tackling the toughest welding challenges in corrosive environments. This nickel-chromium-molybdenum alloy rod is designed for welding Hastelloy C276 and similar materials, delivering unmatched corrosion resistance and strength. Whether you’re joining nickel-based alloys, stainless steels, or cladding steel, our welding rod ensures high-quality welds that stand up to harsh conditions like pitting, stress corrosion cracking, and crevice corrosion. With excellent weldability and a composition that includes 15-17% molybdenum, 14-16% chromium, and trace elements like tungsten, it’s built for reliability in extreme settings.

For more other size details, pls directly contact us

The demand for high-performance welding materials like ERNiCrMo-4 is on the rise, driven by growth in industries that operate in corrosive environments. Chemical processing, oil and gas, and power generation are seeing steady expansion, with global chemical production expected to grow at a CAGR of 3.5% through 2030. This growth fuels the need for materials that can withstand harsh conditions, such as wet chlorine gas, acidic solutions, and seawater. Meanwhile, sustainability trends are pushing manufacturers to prioritize durable, long-lasting materials to reduce maintenance costs and environmental impact.

Welding technology is also evolving. Advances in micro-controlled GTAW and laser welding are improving precision, especially for thin materials like Hastelloy C276. The shift toward automation and digital welding systems is increasing efficiency, but the core need for reliable filler metals remains unchanged. Our ERNiCrMo-4 welding rod meets these demands, offering compatibility with modern welding techniques while maintaining superior performance in traditional methods.

| AWS Classification | Applications |

| ERNiCr-3 | Used for welding 600, 601, and 800 alloys and dissimilar welding between stainless steel and carbon steel |

| ERNiCrFe-7 | Suitable for welding nickel-chromium-iron alloys under ASTM B163, B166, B167, and B168 standards |

| ERNiCrFe-6 | Designed for welding steel to nickel-chromium-iron alloys, as well as stainless steel to nickel-based alloys |

| ERNiCrCoMo-1 | Used for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERNiCrMo-3 | Suitable for nickel alloy, carbon steel, stainless steel, and low alloy steel welding, primarily used for 625, 601, 802 alloys, and 9% nickel alloys |

| ERNi-CI | Used for welding commercially pure nickel, malleable cast iron, and gray cast iron |

| ERCuNi | Suitable for welding 70/30, 80/20, and 90/10 copper-nickel alloys |

| ERNiCu-7 | Used for welding nickel-copper alloys such as B127, B163, B164, and B165 |

| ERNi-1 | Designed for welding pure nickel castings and forgings, including those under ASTM B160, B161, B162, and B163 standards |

| ERNiFeMn-CI | Suitable for welding nodular cast iron, ductile iron, malleable cast iron, and gray cast iron, as well as their dissimilar welding to stainless steel, carbon steel, low alloy steel, and various nickel alloys |

| ERNiCrMo-4 | Used for welding nickel-chromium-molybdenum alloys, or for welding nickel-chromium-molybdenum alloys to steel and other nickel-based alloys |

| ERNiCrMo-11 | uitable for self-welding nickel-chromium-molybdenum alloys, dissimilar welding with steel and other nickel alloys, and also for cladding applications |

| ERNiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-3 | Designed for welding nickel-chromium-molybdenum alloys, including 625, 800, 801, 825, and 600 |

| ENiCrFe-3 | Used for welding nickel-chromium-iron alloys and for dissimilar welding with carbon steel |

| ENiCrFe-2 | Suitable for welding austenitic steel, ferritic steel, and high-nickel alloys, also used for 9% nickel alloy welding |

| ENiCu-7 | Primarily used for welding nickel-copper alloys and their dissimilar welding with steel |

| ENiCrFe-7 | Ideal for welding 690 (UNS N06690) nickel-chromium-iron alloys |

| ENiCrMo-4 | Designed for C-276 alloy welding and most nickel-based alloys |

| ENiCrCoMo-1 | Suitable for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERCuNi | Used for welding forged or cast 70/30, 80/20, and 90/10 copper-nickel alloys |

| ENiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-11 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| Welding Wire Type | Density (g/cm³) | Melting Point (°C) | Electrical Conductivity (% IACS) | Coefficient of Thermal Expansion (10⁻⁶/°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Wire | 7.85 | 1450 | 8-10 | 11.8 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Wire | 7.9 | 1350-1450 | 2-5 | 16-17 | 550-650 | 300-400 | 30-40 |

| Aluminum Welding Wire | 2.7 | 600-660 | >60 | 23.1 | 150-200 | 75-100 | >20 |

| Nickel Alloy Welding Wire | 8.4 | 1350-1400 | 1-2 | 13.1 | 600-800 | 400-600 | 30-40 |

| Welding Rod Type | Coating | Electrical Resistivity (10⁻⁶ Ω·cm) | Hardness (HV) | Heat Resistance (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Rod | Acid coated, alkaline coated | 10-15 | 150-200 | < 450 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Rod | Acid coated, alkaline coated | 60-80 | 200-400 | < 800 | 550-750 | 350-450 | 25-35 |

| Cast Iron Welding Rod | Alkaline coated | 90-120 | 250-450 | 300-600 | 300-500 | 150-300 | 10-20 |

| Nickel Alloy Welding Rod | Alkaline coated | 80-100 | 200-300 | < 1200 | 700-900 | 450-650 | 20-35 |

For more other size details, pls directly contact us

Our ERNiCrMo-4 Hastelloy C276 welding rod is a workhorse across multiple industries. In chemical processing, it’s used for reactors, heat exchangers, and piping systems exposed to corrosive substances like hydrochloric acid and chlorine dioxide. Petrochemical plants rely on it for welding components in refineries and pipelines, where resistance to sour gas and high temperatures is critical. In the oil and gas sector, it’s ideal for downhole tubing and valves in offshore rigs, tackling seawater and brine corrosion.

Power generation facilities use our welding rod in flue gas desulfurization systems, where it resists acidic environments. The pharmaceutical industry benefits from its ability to maintain hygiene in reactors and storage tanks, ensuring product integrity. Pulp and paper production, as well as wastewater treatment, also leverage its corrosion resistance for equipment durability. Its versatility extends to dissimilar welding, joining nickel alloys to stainless or carbon steels, and overlaying steel for enhanced corrosion protection.

|

Parameter |

Our ERNiCrMo-4 Hastelloy C276 Welding Rod |

Competitor A |

|---|---|---|

|

Alloy Composition |

Ni, 15-17% Mo, 14-16% Cr, 4-7% Fe, 3-5% W |

Ni, 14-16% Mo, 13-15% Cr, 5-8% Fe |

|

Corrosion Resistance |

Excellent resistance to pitting, crevice, and stress corrosion cracking |

Good resistance, less effective in chloride environments |

|

High-Temperature Strength |

Maintains integrity up to 1900°F (1038°C) |

Limited to 1800°F (982°C) |

|

Weldability |

Superior fusion, minimal defects |

Moderate fusion, occasional porosity |

|

Available Sizes |

0.8mm–5.0mm (MIG, TIG, SMAW) |

1.0mm–4.0mm (MIG, TIG only) |

|

Applications |

Chemical, petrochemical, oil/gas, power, pharma |

Chemical, oil/gas, limited pharma |

|

Standards Compliance |

AWS A5.14, ASME SFA A5.14, UNS N10276 |

AWS A5.14, partial ASME compliance |

|

Cost-Effectiveness |

Competitive pricing, high durability |

Higher cost, shorter lifespan |

Our ERNiCrMo-4 Hastelloy C276 welding rod stands out because we prioritize quality, versatility, and customer needs. We use premium raw materials and cutting-edge manufacturing processes to ensure every rod meets stringent AWS A5.14 and ASME SFA A5.14 standards. Our rods are engineered for easy striking and re-striking, producing porosity-free welds that reduce rework and save time. Unlike competitors, we offer a wider range of sizes and forms, making our product adaptable to various welding setups and project scales.

We also focus on cost-effectiveness without compromising performance. Our welding rod’s durability means fewer replacements and lower maintenance costs, providing long-term value. Our global supply chain ensures fast delivery to industries worldwide, from North America to Asia. Plus, our dedicated support team offers tailored welding guidance, helping you optimize parameters for the best results. We’re committed to innovation, constantly refining our products to meet evolving industry demands, like sustainability and automation compatibility.

In chemical processing, our ERNiCrMo-4 welding rod is a game-changer. It’s used in reactors and piping systems handling aggressive chemicals like wet chlorine gas and acetic acid. Its low carbon content prevents grain boundary precipitates in the weld zone, ensuring long-lasting equipment. In petrochemical plants, it’s trusted for cladding steel to protect against corrosion, extending the life of pipelines and storage tanks. The oil and gas industry benefits from its ability to withstand sour gas and seawater, critical for offshore platforms.

Power generation plants use our rod in flue gas desulfurization systems, where it resists acidic gases and high temperatures. In pharmaceuticals, it ensures hygienic welds in reactors, preventing contamination. Pulp and paper plants rely on it for digesters and bleach systems, while wastewater treatment facilities use it for equipment exposed to corrosive sludge. Its versatility in dissimilar welding makes it ideal for complex projects, like joining nickel alloys to carbon steel in chemical plants.

The rod’s high molybdenum content (15-17%) provides superior resistance to pitting and crevice corrosion, especially in chloride-rich environments. Its chromium content (14-16%) enhances oxidation resistance, making it reliable in high-temperature settings up to 1900°F. The addition of tungsten and low carbon ensures strong, ductile welds that maintain integrity under stress. These properties make our product a standout for demanding applications.

The welding industry is evolving with a focus on sustainability and efficiency. As chemical processing and oil and gas sectors grow, the demand for corrosion-resistant materials like ERNiCrMo-4 is increasing. The global welding consumables market is projected to reach $18.5 billion by 2027, driven by infrastructure development and energy sector expansion. Automation and digital welding technologies, like micro-GTAW and laser welding, are gaining traction, and our welding rod is designed to perform seamlessly with these advancements.

Sustainability is another key trend. Industries are prioritizing materials that reduce downtime and maintenance, aligning with environmental goals. Our ERNiCrMo-4 rod’s durability supports these objectives by minimizing replacements and waste. The rise of green energy, like hydrogen production, is also creating new applications for corrosion-resistant alloys in harsh chemical environments. We’re staying ahead by investing in R&D to enhance our rod’s compatibility with emerging technologies and eco-friendly practices.

Our welding rod isn’t just a product—it’s a solution for industries facing the toughest corrosion challenges. Its superior composition ensures reliable welds in aggressive environments, from chemical reactors to offshore rigs. We’ve fine-tuned our manufacturing to deliver consistent quality, with rods that offer easy weldability and minimal defects. Our global reach means you get fast delivery and expert support, no matter where your project is.

Compared to others, our rod offers a wider size range, better corrosion resistance, and higher temperature performance. It’s built to meet the needs of modern industries while keeping costs competitive. Whether you’re welding in a chemical plant or a power facility, our ERNiCrMo-4 Hastelloy C276 welding rod delivers the strength, durability, and reliability you need to get the job done right.

About Us:

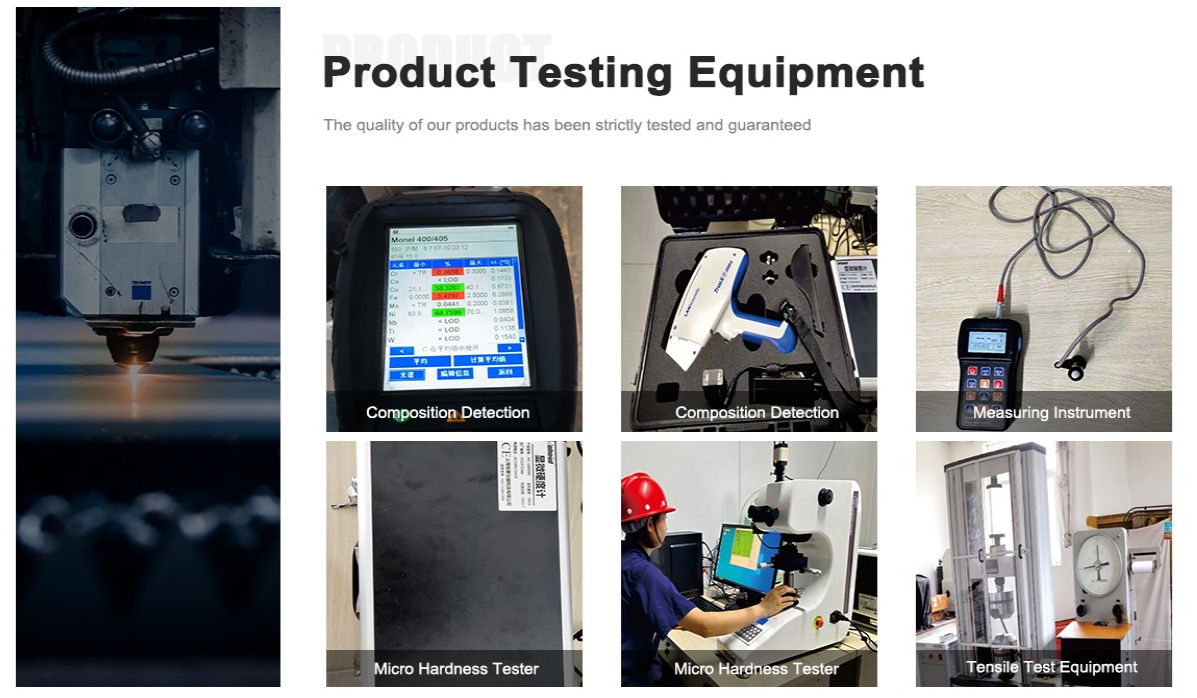

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is ERNiCrMo-4 Hastelloy C276 welding rod used for?

It’s used for welding Hastelloy C276 and similar alloys, as well as dissimilar metals like stainless and carbon steels, in corrosive environments like chemical processing and oil and gas.

What industries benefit from this welding rod?

Chemical processing, petrochemical, oil and gas, power generation, pharmaceuticals, pulp and paper, and wastewater treatment.

What makes this welding rod corrosion-resistant?

Its high molybdenum (15-17%) and chromium (14-16%) content provides excellent resistance to pitting, stress corrosion cracking, and crevice corrosion.

Can it be used for high-temperature applications?

Yes, it maintains strength and integrity in oxidizing atmospheres up to 1900°F (1038°C).

What welding processes is it compatible with?

It works with GTAW (TIG), GMAW (MIG), and SMAW (stick) welding processes.

What sizes are available for the ERNiCrMo-4 welding rod?

Diameters range from 0.8mm to 5.0mm, available in MIG spools, TIG cut lengths, reels, and coils.

Does it require special welding techniques?

Standard welding procedures work, but proper heat input control and post-weld heat treatment ensure optimal results.

Why choose this welding rod for dissimilar welding?

Its composition ensures strong, corrosion-resistant welds when joining nickel alloys to stainless or carbon steels.