Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nickel Welding Wire

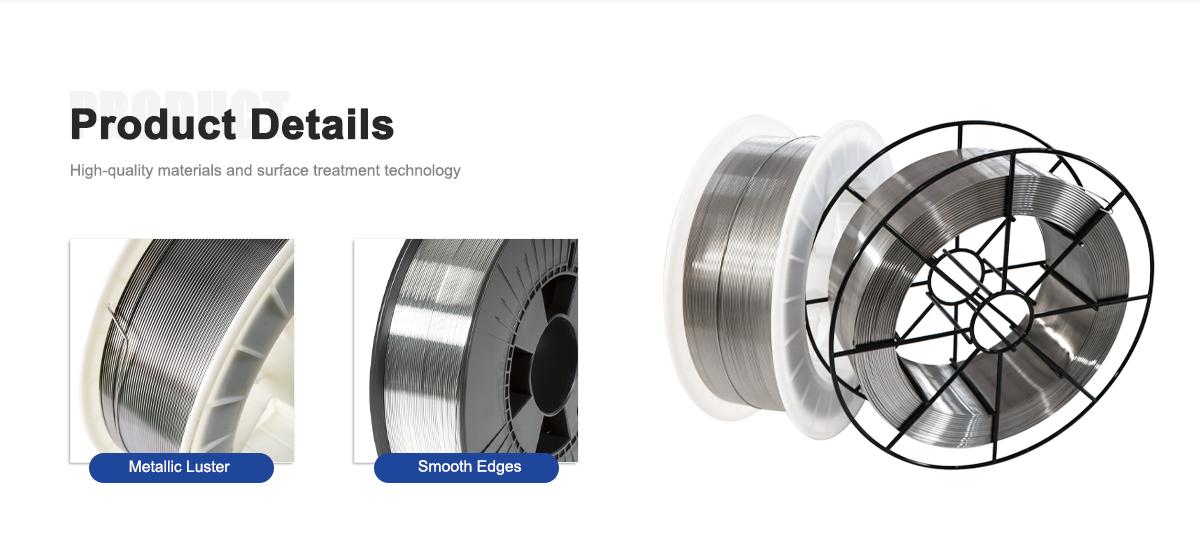

Product Details

We’re proud to offer ERNiCrMo-3 Inconel 625 Welding Wire , a top-tier solution for industries tackling extreme conditions. This nickel-chromium-molybdenum alloy wire is engineered for high-temperature aerospace applications, but its versatility makes it a go-to choice across multiple sectors. Let’s dive into what makes this product stand out, explore its applications Further details can be found in the industries it serves, analyze market trends, and highlight why our company’s expertise sets us apart.

For more other size details, pls directly contact us

ERNiCrMo-3, commonly known as Inconel 625 welding wire, is a nickel-based filler metal designed for welding high-performance alloys like Inconel 601, 625, and 690, as well as Incoloy 800, 825, and 800HT. Its unique composition—roughly 61% nickel, 22% chromium, 9% molybdenum, and 3.5% niobium—delivers exceptional strength, corrosion resistance, and stability at temperatures ranging from cryogenic to 1800°F. This makes it perfect for environments where other materials would fail, like jet engines or chemical reactors.

What sets ERNiCrMo-3 apart is its ability to weld dissimilar metals, such as nickel alloys to carbon steel or stainless steel, without compromising the joint’s integrity. It’s compatible with MIG, TIG, submerged arc, and plasma arc welding, offering flexibility for various welding setups. The wire produces a stable arc with minimal spatter, ensuring clean, precise welds whether you’re working manually or with automated systems. Its low iron content (less than 1%) minimizes dilution, making it ideal for applications requiring strict material purity.

Our ERNiCrMo-3 wire meets AWS A5.14 standards and comes in various diameters, typically 1.2 mm for wire arc additive manufacturing (WAAM) or traditional welding. It’s a reliable choice for projects demanding durability, corrosion resistance, and high mechanical performance.

| AWS Classification | Applications |

| ERNiCr-3 | Used for welding 600, 601, and 800 alloys and dissimilar welding between stainless steel and carbon steel |

| ERNiCrFe-7 | Suitable for welding nickel-chromium-iron alloys under ASTM B163, B166, B167, and B168 standards |

| ERNiCrFe-6 | Designed for welding steel to nickel-chromium-iron alloys, as well as stainless steel to nickel-based alloys |

| ERNiCrCoMo-1 | Used for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERNiCrMo-3 | Suitable for nickel alloy, carbon steel, stainless steel, and low alloy steel welding, primarily used for 625, 601, 802 alloys, and 9% nickel alloys |

| ERNi-CI | Used for welding commercially pure nickel, malleable cast iron, and gray cast iron |

| ERCuNi | Suitable for welding 70/30, 80/20, and 90/10 copper-nickel alloys |

| ERNiCu-7 | Used for welding nickel-copper alloys such as B127, B163, B164, and B165 |

| ERNi-1 | Designed for welding pure nickel castings and forgings, including those under ASTM B160, B161, B162, and B163 standards |

| ERNiFeMn-CI | Suitable for welding nodular cast iron, ductile iron, malleable cast iron, and gray cast iron, as well as their dissimilar welding to stainless steel, carbon steel, low alloy steel, and various nickel alloys |

| ERNiCrMo-4 | Used for welding nickel-chromium-molybdenum alloys, or for welding nickel-chromium-molybdenum alloys to steel and other nickel-based alloys |

| ERNiCrMo-11 | uitable for self-welding nickel-chromium-molybdenum alloys, dissimilar welding with steel and other nickel alloys, and also for cladding applications |

| ERNiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-3 | Designed for welding nickel-chromium-molybdenum alloys, including 625, 800, 801, 825, and 600 |

| ENiCrFe-3 | Used for welding nickel-chromium-iron alloys and for dissimilar welding with carbon steel |

| ENiCrFe-2 | Suitable for welding austenitic steel, ferritic steel, and high-nickel alloys, also used for 9% nickel alloy welding |

| ENiCu-7 | Primarily used for welding nickel-copper alloys and their dissimilar welding with steel |

| ENiCrFe-7 | Ideal for welding 690 (UNS N06690) nickel-chromium-iron alloys |

| ENiCrMo-4 | Designed for C-276 alloy welding and most nickel-based alloys |

| ENiCrCoMo-1 | Suitable for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERCuNi | Used for welding forged or cast 70/30, 80/20, and 90/10 copper-nickel alloys |

| ENiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-11 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| Welding Wire Type | Density (g/cm³) | Melting Point (°C) | Electrical Conductivity (% IACS) | Coefficient of Thermal Expansion (10⁻⁶/°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Wire | 7.85 | 1450 | 8-10 | 11.8 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Wire | 7.9 | 1350-1450 | 2-5 | 16-17 | 550-650 | 300-400 | 30-40 |

| Aluminum Welding Wire | 2.7 | 600-660 | >60 | 23.1 | 150-200 | 75-100 | >20 |

| Nickel Alloy Welding Wire | 8.4 | 1350-1400 | 1-2 | 13.1 | 600-800 | 400-600 | 30-40 |

| Welding Rod Type | Coating | Electrical Resistivity (10⁻⁶ Ω·cm) | Hardness (HV) | Heat Resistance (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Rod | Acid coated, alkaline coated | 10-15 | 150-200 | < 450 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Rod | Acid coated, alkaline coated | 60-80 | 200-400 | < 800 | 550-750 | 350-450 | 25-35 |

| Cast Iron Welding Rod | Alkaline coated | 90-120 | 250-450 | 300-600 | 300-500 | 150-300 | 10-20 |

| Nickel Alloy Welding Rod | Alkaline coated | 80-100 | 200-300 | < 1200 | 700-900 | 450-650 | 20-35 |

For more other size details, pls directly contact us

The global demand for high-performance welding materials like ERNiCrMo-3 is on the rise, driven by growth in aerospace, energy, and chemical processing sectors. According to recent market insights, the nickel alloy welding consumables market is projected to grow steadily through 2030, fueled by increasing investments in aerospace infrastructure and renewable energy projects. Aerospace, in particular, is a key driver, with global air travel recovering and defense budgets expanding for advanced aircraft and spacecraft.

In the energy sector, oil and gas exploration in harsh environments, like deep-sea drilling, relies on materials that can withstand corrosion from seawater and acidic chemicals. Similarly, the push for cleaner energy has boosted demand for nuclear reactor components, where ERNiCrMo-3 excels due to its resistance to radiation and high temperatures. The chemical processing industry also leans heavily on this wire for equipment like heat exchangers and pressure vessels, which face aggressive corrosive media.

Additive manufacturing (AM) is another game-changer. Wire arc additive manufacturing (WAAM) using ERNiCrMo-3 is gaining traction for producing complex aerospace components with less material waste compared to traditional machining. Studies show WAAM can cut energy consumption by up to three times and reduce material waste from 85% to 35% for Inconel 625 parts. This aligns with the industry’s shift toward sustainability, making our wire a forward-thinking choice for modern manufacturing.

However, challenges like high material costs and the need for skilled welders persist. The industry is addressing this through automation and advanced welding techniques, like cold metal transfer (CMT), which reduces heat input and improves precision. As these technologies evolve, ERNiCrMo-3 remains a staple for its adaptability and performance.

ERNiCrMo-3 Inconel 625 welding wire shines in demanding applications across multiple industries:

Aerospace: We supply wire for jet engine components like turbine seals, exhaust systems, and ducting, where high strength and resistance to thermal fatigue are critical. Its ability to maintain integrity at 1800°F ensures reliable performance in extreme conditions.

Chemical Processing: Our wire is used to weld heat exchangers, pipelines, and tanks that handle corrosive chemicals like phosphoric and organic acids. Its resistance to pitting and crevice corrosion ensures long-lasting equipment.

Marine: In seawater environments, ERNiCrMo-3 prevents corrosion in offshore structures and ship components, making it a favorite for marine engineering.

Nuclear: The wire’s stability in high-radiation environments makes it ideal for reactor cores and fuel rods in nuclear power plants.

Oil and Gas: From deep-sea pipelines to refineries, our wire ensures leak-proof, durable welds in corrosive and high-pressure settings.

Additive Manufacturing: WAAM using ERNiCrMo-3 allows for precise, efficient production of complex parts, reducing waste and lead times for aerospace and defense components.

Its versatility also extends to welding dissimilar metals, such as Inconel to stainless steel, which is crucial for hybrid structures in aerospace and energy systems.

When it comes to ERNiCrMo-3 Inconel 625 welding wire, we stand out in a crowded market. While other suppliers offer similar products, our focus on quality, innovation, and customer support gives us an edge. Here’s why:

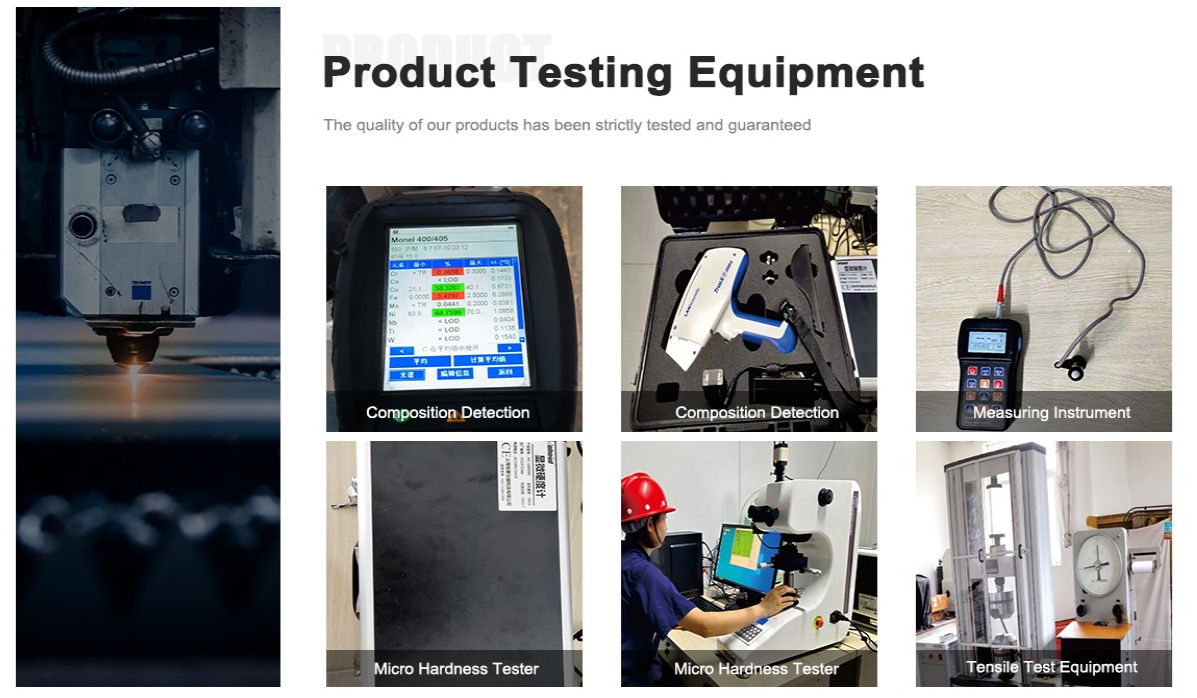

Uncompromising Quality: Our wire is manufactured to strict AWS A5.14 standards, with rigorous quality control ensuring low iron content and consistent composition. Every batch is tested for weldability and corrosion resistance, so you get reliable performance every time.

Extensive Inventory: We maintain a large stock of ERNiCrMo-3 in various diameters and forms, ready for immediate delivery. This reduces downtime and keeps your projects on schedule, unlike competitors with limited stock.

Technical Expertise: Our team of welding engineers provides hands-on support, from selecting the right wire to optimizing welding parameters. We help you achieve flawless welds, even for complex aerospace applications.

Logistics Excellence: With a global distribution network, we ensure fast, cost-effective delivery to your site, whether you’re in Saudi Arabia’s oil fields or an aerospace hub in the U.S. Our competitors often struggle with lead times.

Sustainability Focus: We embrace eco-friendly manufacturing practices, like WAAM-compatible wire that reduces waste and energy use. This aligns with industry trends toward greener production, giving you a sustainable edge.

Custom Solutions: Need a specific diameter or packaging? We tailor our products to your project’s needs, offering flexibility that generic suppliers can’t match.

Other companies may cut corners on quality or lack the expertise to support high-stakes applications. We prioritize precision, reliability, and customer success, making us the preferred partner for aerospace and beyond.

|

Parameter |

ERNiCrMo-3 Inconel 625 |

Other Nickel-Based Wires |

|---|---|---|

|

Main Composition |

Ni, Cr, Mo, Nb |

Ni, Cr, varying Mo or Fe |

|

Temperature Resistance |

Up to 1800°F |

Up to 1500–1700°F |

|

Corrosion Resistance |

Excellent (seawater, acids) |

Good, but less versatile |

|

Weldability |

High (stable arc) |

Moderate to high |

|

Dissimilar Metal Welding |

Yes (steel, stainless) |

Limited compatibility |

|

Tensile Strength |

High (~120 ksi) |

Moderate (~80–100 ksi) |

|

Applications |

Aerospace, marine, nuclear |

General industrial use |

|

Cost Efficiency |

Premium, high durability |

Lower cost, less durable |

The welding industry is evolving fast, and ERNiCrMo-3 is at the forefront. Automation is transforming welding processes, with robotic systems and CMT reducing human error and improving efficiency. Our wire is optimized for these technologies, delivering consistent results in automated setups. The rise of additive manufacturing is another trend to watch. WAAM, using our ERNiCrMo-3 wire, is revolutionizing how aerospace components are made, offering faster production and lower costs compared to traditional methods.

Sustainability is also shaping the market. Industries are under pressure to reduce waste and energy use, and our wire supports this through efficient WAAM processes and durable welds that extend equipment lifespans. As aerospace and energy sectors grow, demand for high-performance materials like ERNiCrMo-3 will only increase, especially in regions like Asia-Pacific and the Middle East, where infrastructure investments are soaring.

Our ERNiCrMo-3 Inconel 625 welding wire is more than just a product—it’s a solution for the toughest challenges in aerospace, energy, and beyond. Its unmatched strength, corrosion resistance, and weldability make it a must-have for high-temperature applications. Backed by our commitment to quality, fast delivery, and expert support, we’re here to help you build stronger, longer-lasting components. Whether you’re welding a jet engine or a chemical reactor, our wire delivers the performance you need to stay ahead.

Ready to elevate your projects? Contact us today to learn how our ERNiCrMo-3 wire can meet your needs and keep your operations running smoothly.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is ERNiCrMo-3 Inconel 625 welding wire used for?

It’s used for welding nickel-based alloys like Inconel 601, 625, and 690, and Incoloy 800, 825, and 800HT, especially in high-temperature and corrosive environments like aerospace, chemical processing, and marine applications.

What industries rely on ERNiCrMo-3 welding wire?

Aerospace, oil and gas, chemical processing, marine, and nuclear industries use it for its strength and corrosion resistance in extreme conditions.

Can ERNiCrMo-3 weld dissimilar metals?

Yes, it’s great for joining nickel-based alloys to carbon steel, low alloy steel, and stainless steel, ensuring strong, reliable welds.

What makes ERNiCrMo-3 suitable for high-temperature applications?

Its nickel-chromium-molybdenum composition provides excellent resistance to oxidation and creep, maintaining strength up to 1800°F.

How does ERNiCrMo-3 perform in corrosive environments?

It resists pitting, crevice corrosion, and stress corrosion cracking in harsh environments like seawater and acidic conditions.

What welding processes work with ERNiCrMo-3?

It’s compatible with MIG, TIG, submerged arc, and plasma arc welding, offering versatility for various setups.

Why choose ERNiCrMo-3 for aerospace?

Its high strength, fatigue resistance, and ability to withstand extreme temperatures make it ideal for jet engine components and turbine seals.

Is ERNiCrMo-3 easy to use for welders?

Yes, it offers excellent weldability with a stable arc and minimal spatter, suitable for both manual and automated welding.