Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nickel Welding Wire

Product Details

Our Durable ERCuNi MIG/TIG Welding Wire is built to tackle the toughest welding challenges in desalination, chemical processing, and beyond. This high-strength wire is crafted for joining copper-nickel (CuNi) alloys like 70/30 and 90/10, delivering welds that stand up to corrosion, high temperatures, and harsh environments. Meeting AWS A5.7 and ASME SFA A5.7 standards, it’s a reliable choice for industries where failure isn’t an option.

The wire’s composition—primarily copper with ~30% nickel, plus small amounts of manganese, iron, and titanium—gives it a unique edge. It boasts a tensile strength of around 80,000 psi and 30% elongation, ensuring welds that are both strong and flexible. Whether you’re using MIG (GMAW) for high-speed production or TIG (GTAW) for precision work, our ERCuNi wire delivers clean, consistent results. Its melting range of 1290–1350°C and density of 8.84 g/cm³ make it a stable performer, while its 30% IACS electrical conductivity suits applications needing efficient current transfer.

For steel overlays, we recommend a nickel alloy barrier layer with MIG welding to ensure a robust bond. This wire’s standout feature is its exceptional resistance to saltwater, chemicals, and pitting corrosion, making it a top pick for desalination plants, chemical reactors, and marine systems. It’s not just a welding wire—it’s a solution for projects that demand durability and reliability.

For more other size details, pls directly contact us

The welding consumables market is booming, driven by growing demand for high-performance materials in industries like desalination, chemical processing, and marine engineering. Copper-nickel alloys are gaining traction due to their ability to withstand corrosive environments, particularly in water-intensive applications. The global desalination market, for instance, is expanding rapidly as water scarcity pushes investment in new plants and upgrades to existing ones. Similarly, chemical processing is seeing increased demand for materials that can handle aggressive substances without degrading.

Sustainability is a big driver in today’s industrial landscape. Companies are looking for welding solutions that reduce maintenance costs and extend equipment lifespan. Our ERCuNi wire fits the bill, offering welds that resist corrosion and wear, cutting down on repairs and replacements. Automation is another trend reshaping the industry, with MIG and TIG welding processes increasingly integrated into robotic systems for faster, more precise production. Our wire’s consistent performance makes it ideal for these high-tech setups.

The rise of renewable energy, particularly offshore wind and tidal power, is creating new opportunities for CuNi welding solutions. These projects require materials that can endure constant exposure to seawater and extreme weather, aligning perfectly with our wire’s strengths. Meanwhile, the oil and gas sector continues to rely on copper-nickel alloys for pipelines, valves, and processing equipment, further fueling demand for reliable welding consumables.

| AWS Classification | Applications |

| ERNiCr-3 | Used for welding 600, 601, and 800 alloys and dissimilar welding between stainless steel and carbon steel |

| ERNiCrFe-7 | Suitable for welding nickel-chromium-iron alloys under ASTM B163, B166, B167, and B168 standards |

| ERNiCrFe-6 | Designed for welding steel to nickel-chromium-iron alloys, as well as stainless steel to nickel-based alloys |

| ERNiCrCoMo-1 | Used for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERNiCrMo-3 | Suitable for nickel alloy, carbon steel, stainless steel, and low alloy steel welding, primarily used for 625, 601, 802 alloys, and 9% nickel alloys |

| ERNi-CI | Used for welding commercially pure nickel, malleable cast iron, and gray cast iron |

| ERCuNi | Suitable for welding 70/30, 80/20, and 90/10 copper-nickel alloys |

| ERNiCu-7 | Used for welding nickel-copper alloys such as B127, B163, B164, and B165 |

| ERNi-1 | Designed for welding pure nickel castings and forgings, including those under ASTM B160, B161, B162, and B163 standards |

| ERNiFeMn-CI | Suitable for welding nodular cast iron, ductile iron, malleable cast iron, and gray cast iron, as well as their dissimilar welding to stainless steel, carbon steel, low alloy steel, and various nickel alloys |

| ERNiCrMo-4 | Used for welding nickel-chromium-molybdenum alloys, or for welding nickel-chromium-molybdenum alloys to steel and other nickel-based alloys |

| ERNiCrMo-11 | uitable for self-welding nickel-chromium-molybdenum alloys, dissimilar welding with steel and other nickel alloys, and also for cladding applications |

| ERNiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-3 | Designed for welding nickel-chromium-molybdenum alloys, including 625, 800, 801, 825, and 600 |

| ENiCrFe-3 | Used for welding nickel-chromium-iron alloys and for dissimilar welding with carbon steel |

| ENiCrFe-2 | Suitable for welding austenitic steel, ferritic steel, and high-nickel alloys, also used for 9% nickel alloy welding |

| ENiCu-7 | Primarily used for welding nickel-copper alloys and their dissimilar welding with steel |

| ENiCrFe-7 | Ideal for welding 690 (UNS N06690) nickel-chromium-iron alloys |

| ENiCrMo-4 | Designed for C-276 alloy welding and most nickel-based alloys |

| ENiCrCoMo-1 | Suitable for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERCuNi | Used for welding forged or cast 70/30, 80/20, and 90/10 copper-nickel alloys |

| ENiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-11 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| Welding Wire Type | Density (g/cm³) | Melting Point (°C) | Electrical Conductivity (% IACS) | Coefficient of Thermal Expansion (10⁻⁶/°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Wire | 7.85 | 1450 | 8-10 | 11.8 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Wire | 7.9 | 1350-1450 | 2-5 | 16-17 | 550-650 | 300-400 | 30-40 |

| Aluminum Welding Wire | 2.7 | 600-660 | >60 | 23.1 | 150-200 | 75-100 | >20 |

| Nickel Alloy Welding Wire | 8.4 | 1350-1400 | 1-2 | 13.1 | 600-800 | 400-600 | 30-40 |

| Welding Rod Type | Coating | Electrical Resistivity (10⁻⁶ Ω·cm) | Hardness (HV) | Heat Resistance (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Rod | Acid coated, alkaline coated | 10-15 | 150-200 | < 450 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Rod | Acid coated, alkaline coated | 60-80 | 200-400 | < 800 | 550-750 | 350-450 | 25-35 |

| Cast Iron Welding Rod | Alkaline coated | 90-120 | 250-450 | 300-600 | 300-500 | 150-300 | 10-20 |

| Nickel Alloy Welding Rod | Alkaline coated | 80-100 | 200-300 | < 1200 | 700-900 | 450-650 | 20-35 |

For more other size details, pls directly contact us

Our ERCuNi welding wire is a versatile powerhouse, trusted across industries for its durability and corrosion resistance. Here’s where it makes a difference:

Desalination Plants: From evaporators to brine heaters, our wire is used to weld CuNi components that withstand constant saltwater exposure. Its resistance to pitting and crevice corrosion ensures long-lasting performance in desalination systems.

Chemical Processing: In reactors, piping, and storage tanks, our ERCuNi wire delivers welds that resist chemical attack and high temperatures, making it ideal for handling acids, alkalis, and other corrosive substances.

Marine Applications: Shipbuilding, offshore platforms, and marine hardware rely on our wire for welding propellers, hulls, and fittings. Its ability to resist seawater corrosion makes it a go-to for harsh marine environments.

Oil and Gas: Our wire is used to join CuNi pipes and fittings in pipelines and processing equipment, ensuring leak-free, durable connections that handle high-pressure and corrosive fluids.

Heat Exchangers: The wire’s thermal stability makes it perfect for heat exchangers in power plants and chemical facilities, where welds must endure thermal cycling without cracking.

Its compatibility with both MIG and TIG welding gives you flexibility to tackle diverse projects, from high-volume production to intricate repairs. The wire also performs well in dissimilar metal welding, joining CuNi alloys to stainless or carbon steel with ease. For cryogenic applications, like LNG systems, its toughness at low temperatures adds even more value.

We’re not just in the business of selling welding wire—we’re here to help you succeed. Our Durable ERCuNi MIG/TIG Welding Wire is manufactured with precision, meeting AWS A5.7 and ASME standards to ensure top-quality performance. Here’s what makes us stand out:

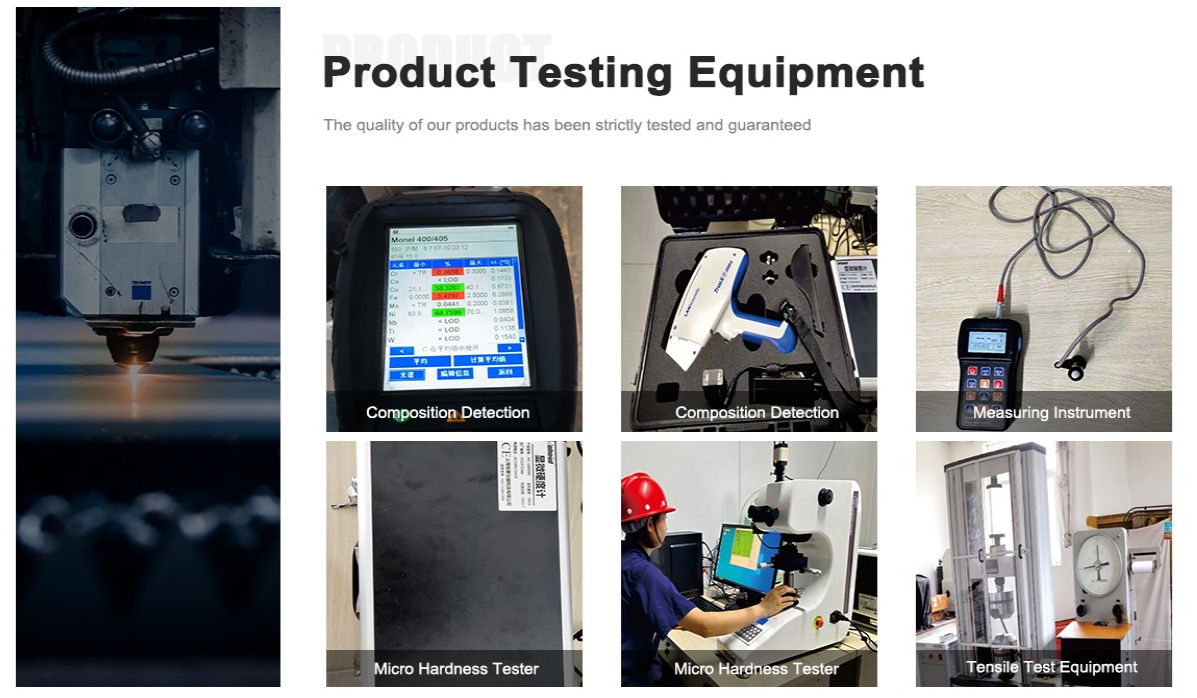

Superior Quality: Every spool undergoes rigorous testing for composition, weldability, and mechanical properties. You get a product you can trust for consistent, high-quality welds.

Custom Options: We offer ERCuNi wire in various diameters and forms (wire, rod, or strip) to match your project’s needs, whether it’s MIG or TIG welding.

Expert Support: Our team of welding specialists is ready to assist, from selecting the right wire to optimizing your welding process. We provide practical advice, like using a nickel alloy barrier for steel overlays, to ensure flawless results.

Fast, Reliable Delivery: We know delays can kill a project. Our efficient supply chain ensures you get your wire when you need it, keeping your timeline on track.

Eco-Friendly Focus: Our wire’s durability reduces the need for frequent repairs, saving you money and aligning with sustainable practices by minimizing waste.

Compared to other CuNi welding wires, ours offers higher tensile strength (~80,000 psi vs. 65,000–75,000 psi) and better elongation (~30% vs. 20–28%). Its corrosion resistance is unmatched, especially in saltwater and chemical environments, and its compatibility with both MIG and TIG processes gives you more flexibility than many alternatives. While some competitors’ products may require complex pre-treatments or fall short on industry standards, our wire is straightforward to use and fully compliant.

Parameter | Our ERCuNi MIG/TIG Wire | Other CuNi Welding Wires |

|---|---|---|

Composition | Cu (remainder), ~30% Ni, ≤1% Mn, ≤0.5% Fe | Varies, often lower Ni or additives |

Tensile Strength | ~80,000 psi | 65,000–75,000 psi |

Elongation | ~30% | 20–28% |

Corrosion Resistance | Outstanding (saltwater, chemicals) | Good, but less consistent |

Welding Processes | MIG, TIG | Often limited to one process |

Applications | Desalination, chemical, marine, oil & gas | Narrower range, less versatile |

Preheat Requirements | Nickel alloy barrier for steel overlays | May require complex pre-treatments |

Standards Compliance | AWS A5.7, ASME SFA A5.7 | May not fully meet AWS standards |

The future looks bright for copper-nickel welding solutions like our ERCuNi wire. The desalination industry is growing fast, with new plants popping up in water-scarce regions like the Middle East and Asia. Chemical processing is also expanding, driven by demand for advanced materials in pharmaceuticals, petrochemicals, and renewable fuels. These trends point to a rising need for reliable, corrosion-resistant welding consumables.

Automation is transforming the welding landscape, with robotic MIG and TIG systems becoming standard in high-volume industries like desalination and shipbuilding. Our wire’s consistent feedability and weld quality make it a perfect fit for these automated setups. The push for offshore renewable energy, like wind and tidal farms, is another growth area, as these projects demand materials that can handle relentless saltwater exposure.

Innovations in material science, including AI-driven alloy development, could lead to even stronger CuNi solutions down the line. For now, our ERCuNi wire remains a top performer, meeting the needs of today’s toughest applications while keeping pace with industry trends.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is ERCuNi MIG/TIG welding wire used for?

It’s designed for welding copper-nickel alloys, especially in desalination plants, chemical processing, and marine applications.

Which welding processes are compatible with ERCuNi wire?

It works seamlessly with MIG (GMAW) and TIG (GTAW) welding, offering flexibility for various projects.

Why is ERCuNi ideal for desalination plants?

Its superior resistance to saltwater corrosion and erosion makes it perfect for desalination equipment exposed to harsh conditions.

What’s the typical composition of ERCuNi welding wire?

It’s mostly copper with ~30% nickel, plus traces of manganese, iron, and titanium for enhanced strength and weldability.

Is pre-weld preparation needed for ERCuNi?

For steel overlays, a nickel alloy barrier layer is recommended with MIG to ensure a clean, strong weld.

Which industries benefit most from ERCuNi wire?

Desalination, chemical processing, marine, and oil and gas industries rely on it for durable, corrosion-resistant welds.

How does ERCuNi perform in corrosive environments?

It excels in resisting pitting, crevice corrosion, and chemical attack, ensuring long-lasting welds in aggressive settings.

What are the mechanical properties of ERCuNi welds?

Welds typically achieve ~80,000 psi tensile strength and ~30% elongation, balancing strength and flexibility.