Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Thermal Spray Wire

Product Details

Our 45CT nickel-chromium-titanium wire is built to tackle sulfidation head-on, delivering top-tier corrosion protection for industrial equipment like boiler tubes and turbine components. This isn’t just wire—it’s a game-changer for industries facing harsh, sulfur-rich environments. Let’s dive into what makes our 45CT wire stand out, from its robust materials to its critical applications, while exploring industry trends and why our company is the go-to choice for reliable, long-lasting coatings.

For more other size details, pls directly contact us

We craft our 45CT wire from a high-performance Ni-Cr-Ti alloy, with a nickel base, 43-45% chromium, and 0.7% titanium, plus low carbon to keep it weldable and crack-resistant. The high chromium content forms a tough oxide layer that fights off sulfur-induced corrosion, while titanium boosts resistance to sulfidation and oxidation at temperatures up to 1000°C. Available in standard diameters like 1.6mm or 3.2mm, it’s designed for arc spraying, creating dense, adherent coatings that bond tightly to substrates like steel or alloy tubes. Our wire is rigorously tested to ensure purity and consistency, meeting industry standards for thermal spray applications. When sprayed, it forms coatings that show virtually no degradation after 24 months in sulfur-heavy boiler environments, making it ideal for protecting critical infrastructure in power plants or chemical processors.

| Nickel (Ni) | 95% |

| Aluminum (Al) | 5% |

| Melting Point | 1400-1450°C |

| Density | 8.9 g/cm³ |

| Bond Strength | ≥ 55 MPa (Flame spray), ≥ 70 MPa (Electric arc spray) |

| Size | 1.2/1.6/2.0mm |

| Weight of Axle | 15kg |

| Parameter | Recommended Value |

| Spray Voltage | 30-40V |

| Spray Current | 100-300A |

| Air Pressure | 0.4-0.6MPa |

| Spray Distance | 100-150mm |

| Preheat Temperature | 80-150°C |

| Coating Thickness | 0.1-1.5mm |

For more other size details, pls directly contact us

The applications for our 45CT wire are vast and vital. In power generation, it coats boiler tubes—think waterwalls, superheaters, or economizers—shielding them from sulfidation caused by sulfur-laden fuels like coal or biomass. In chemical processing, it protects reactor tubes and heat exchangers from corrosive gases like sulfur dioxide or hydrogen sulfide. We’ve seen it used in waste-to-energy plants, where high-chloride and vanadium environments wreak havoc, extending tube life and cutting maintenance costs. The arc spraying process is simple: melt the wire, spray it onto the surface, and get a coating that resists pitting, spalling, and erosion from ash or slag. In oil refineries, our wire safeguards furnace tubes against sulfur-rich crude oils, while in marine applications, it tackles saltwater-induced corrosion in boiler systems. Its versatility makes it a favorite for both in-shop coating and on-site maintenance, keeping downtime to a minimum.

The thermal spray industry is buzzing, and our 45CT wire is at the forefront. The global market for thermal spray coatings is growing at a 7% CAGR, projected to hit billions by 2032, driven by rising energy demands and stricter environmental regulations. Power plants are burning dirtier fuels like biomass to cut emissions, which ramps up sulfidation risks—our wire is designed for exactly that challenge. Sustainability is a big deal; our recyclable alloy and eco-friendly production processes align with industry pushes for greener solutions. Advancements in arc spraying tech, like high-velocity systems, are making coatings denser and more durable, and our wire is optimized for these innovations. Regulatory bodies are pushing for longer equipment lifespans to reduce waste, and our coatings help boiler tubes last years longer. Supply chain issues, like nickel price spikes, are a hurdle, but our diversified sourcing keeps us reliable. The growth of renewable energy systems, like biomass or hydrogen boilers, is opening new doors where sulfidation resistance is critical.

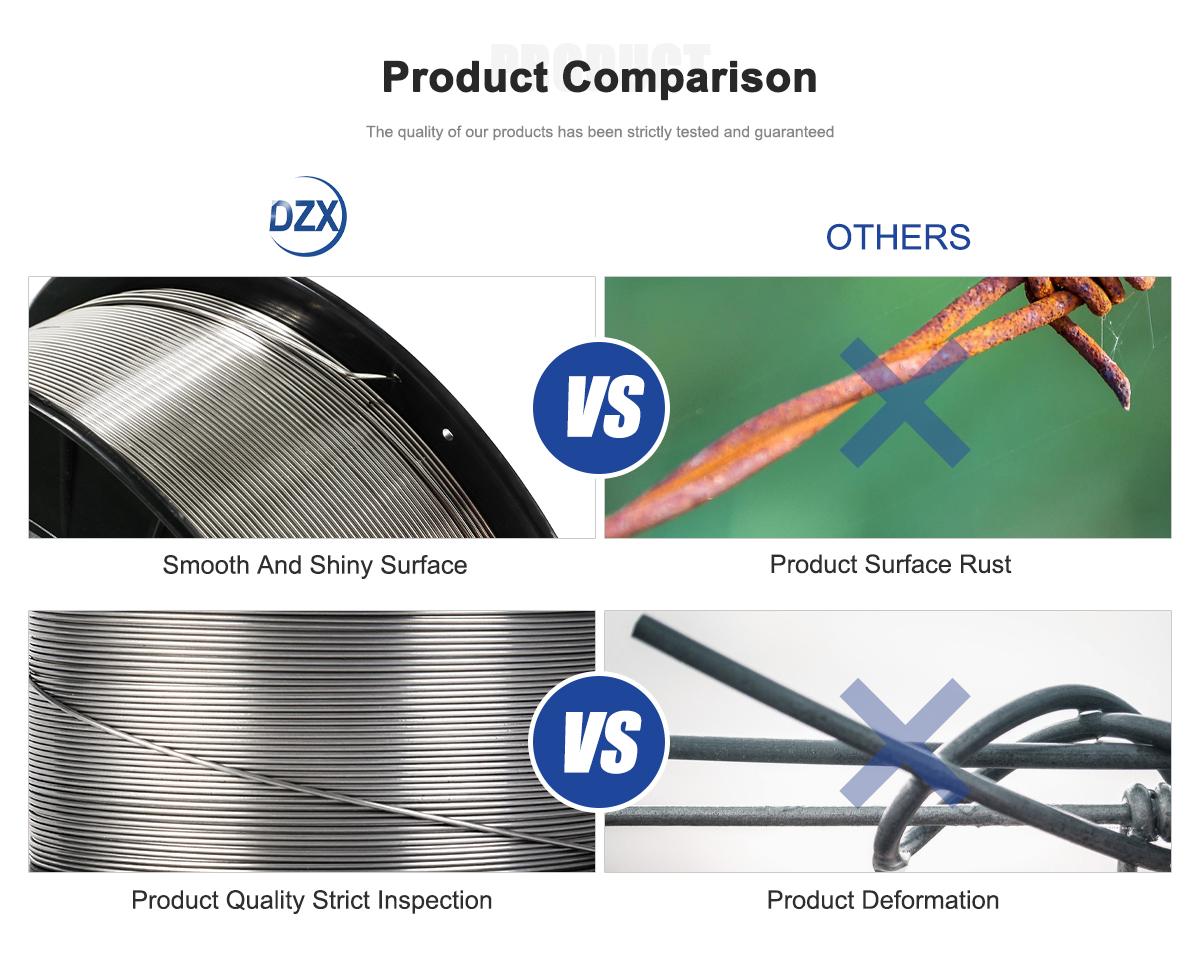

What sets our company apart? It’s our obsession with quality, customization, and performance. We don’t just produce wire; we engineer solutions tailored to your specific needs. Our R&D team fine-tunes the Ni-Cr-Ti alloy to maximize sulfidation resistance, achieving purity levels that outperform standard wires. Need a custom diameter or spooling for your spray system? We deliver tolerances tighter than industry norms, ensuring consistent, defect-free coatings. Our quality control is rigorous—testing for bond strength, corrosion resistance, and coating density in simulated sulfurous environments. We move fast, with streamlined production delivering quick turnarounds, so your maintenance schedules stay on track. Our commitment to sustainability, like using renewable energy in manufacturing, resonates with clients chasing green goals. This blend of precision, speed, and eco-consciousness gives us a clear edge in reliability and innovation.

| Parameter | 45CT NiCrTi Wire | Standard NiCr Wire (e.g., 80/20) |

|---|---|---|

| Composition | Nickel base, 43-45% Chromium, 0.7% Titanium, low carbon | Nickel base, 80% Nickel, 20% Chromium |

| Sulfidation Resistance | Excellent; superior resistance to sulfur-induced corrosion in high-temperature environments | Moderate; less effective in sulfur-rich or chloride-heavy conditions |

| Oxidation Resistance | High; stable up to 1000°C with minimal scaling | Good; suitable up to 900°C but prone to oxidation in extreme heat |

| Wear Resistance | Good; titanium enhances abrasion resistance for industrial applications | Fair; primarily focused on corrosion rather than wear |

| Bond Strength | Superior; dense, well-bonded coatings via arc spraying | Good; reliable but may need additional bond coats for adhesion |

| Temperature Tolerance | Up to 1000°C; ideal for continuous high-heat operations | Up to 900°C; better for intermittent or lower-temperature uses |

| Cost | Higher; premium for specialized sulfidation protection | Lower; cost-effective for general corrosion protection |

| Application Suitability | Boiler tubes, turbine blades, chemical reactors; excels in sulfurous environments | General industrial coatings; less suited for high-sulfur or extreme conditions |

| Coating Durability | Exceptional; minimal thickness loss after 24 months in sulfur-rich settings | Moderate; faster degradation in aggressive sulfurous atmospheres |

| Process Compatibility | Optimized for arc spraying; produces uniform, high-adhesion coatings | Suitable for arc or flame spraying; less specialized for sulfidation resistance |

Let’s talk applications in more detail. Our 45CT wire is a lifesaver for boiler tubes in coal-fired power plants, where sulfur dioxide and fly ash can eat through unprotected surfaces. The titanium addition makes it a champ against vanadium attacks in oil-fired boilers, extending tube life in refineries. In waste incinerators, it protects against chloride-induced corrosion, reducing costly shutdowns. We’ve optimized it for high-pressure, supercritical boilers operating above 600°C, where thermal cycling demands robust coatings. In petrochemical plants, it coats furnace tubes handling sulfur-heavy feedstocks, maintaining efficiency. For emerging hydrogen boilers, our wire’s high-temperature stability ensures protection as industries shift to cleaner fuels. Its ability to form uniform coatings on complex geometries, like turbine blades, also makes it a go-to for aerospace and power generation.

Industry trends are exciting. The push for net-zero emissions is driving demand for durable coatings to extend the life of existing infrastructure, cutting the need for new builds. Asia-Pacific is a hotbed for growth due to rapid industrialization, but North America and Europe are investing heavily in retrofitting aging plants. Economic pressures, like fluctuating chromium prices, challenge the market, but our efficient processes keep costs competitive. Post-COVID, supply chain resilience is critical, and our global facilities ensure consistent delivery. Innovations like nanotechnology-enhanced coatings—think adding nanoparticles for extra hardness—are on the horizon, and we’re exploring those to stay ahead.

Our company’s strength lies in our full-spectrum support. We provide application guidance, from optimizing spray parameters to post-coating inspections, ensuring maximum protection. Our testing labs simulate harsh sulfurous conditions, proving our coatings last longer with less degradation. Compared to typical market options, our 45CT wire offers superior sulfidation resistance and coating density, reducing maintenance frequency. We also provide value-added services like pre-spooled reels for easy handling, which many overlook. This builds trust and long-term partnerships with clients who value uptime and savings.

Product-wise, our 45CT wire is optimized for arc spraying, producing coatings with excellent adhesion and low porosity. The high chromium content creates a stable oxide layer, while titanium enhances sulfidation resistance, making it ideal for boilers burning low-grade fuels. We ensure low impurities to prevent coating weaknesses, and it’s available in various spool sizes for seamless integration. For less aggressive environments, it pairs well with bond coats, but in high-sulfur settings, it stands alone.

Looking ahead, we’re stoked about trends like AI-driven coating monitoring for predictive maintenance. Regulatory shifts toward lower emissions align with our strengths, as our wire helps plants meet compliance by extending equipment life. The rise of biomass and hydrogen boilers increases demand for sulfidation-resistant solutions, and we’re ready to lead. We’re also investing in greener alloy production to cut our carbon footprint.

For more other size details, pls directly contact us

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What materials make up 45CT nickel-chromium-titanium wire?

45CT wire is a Ni-Cr-Ti alloy with a nickel base, 43-45% chromium, 0.7% titanium, and low carbon content for superior sulfidation and corrosion resistance.

What are the primary applications of 45CT wire for sulfidation resistance?

It’s used for thermal spray coatings on boiler tubes, turbine components, and chemical processing equipment to protect against sulfur-induced corrosion and high-temperature oxidation.

How does 45CT wire perform in high-sulfur environments?

It forms dense, adherent coatings that resist sulfidation, pitting, and scaling, maintaining integrity in sulfur-rich atmospheres for up to 24 months.

What industry trends are driving demand for 45CT nickel-chromium-titanium wire?

Trends include growing energy sector needs, focus on sustainable coatings, market expansion at a 7% CAGR through 2032, and advancements in thermal spray technologies.

Is 45CT wire suitable for extreme temperature applications?

Yes, it withstands temperatures up to 1000°C, providing excellent protection against oxidation and sulfidation in high-heat industrial settings.

How do you maintain coatings applied with 45CT wire?

Inspect coatings every 12-18 months, clean off ash or deposits, and reapply as needed every 2-3 years to maintain sulfidation resistance.

How do environmental factors affect 45CT wire coatings?

Coatings resist sulfur, vanadium, and chloride-rich environments, preventing corrosion from acidic gases and high temperatures in boilers or furnaces.

What future trends might impact 45CT wire for sulfidation resistance?

Emerging trends include nanotechnology-enhanced coatings, increased use in renewable energy systems, and eco-friendly alloy production to reduce environmental impact.

Previous article:45CT Thermal Spray Wire for Boiler Tube Corrosion Protection

Next article:Ni80Al20 Wire for Self-Bonding Marine Equipment Coatings