Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Release time:2025-07-10 click here:1749

Our high-quality wires—made from stainless steel, aluminum, nickel alloys, and mild steel—are helping build stronger, lighter, and more durable components that keep planes flying and cars rolling. These industries demand precision and reliability, and our welding solutions are stepping up to the plate, driving innovation and efficiency. Let’s dive into what makes our wires stand out, how they’re used, and where the market’s headed.

Our Welding Wire s are designed to create tough, reliable joints that can handle the toughest conditions. Stainless steel wires deliver exceptional corrosion resistance, making them perfect for parts exposed to harsh environments, like aerospace frames or automotive exhaust systems. Aluminum wires are lightweight and cost-effective, ideal for aircraft panels and car bodies where weight reduction is key. Nickel alloys shine in high-temperature settings, like turbine components, while mild steel is a go-to for structural work due to its strength and affordability.

Each wire type is crafted with specific applications in mind. We offer a range of diameters and flux types to suit different welding processes, like MIG, TIG, and flux-cored arc welding. Whether it’s a thin, precise weld for an aircraft wing or a heavy-duty joint for an automotive chassis, we can customize our wires to get the job done. Our focus on quality ensures consistent performance, reducing defects and rework, which saves time and money for manufacturers.

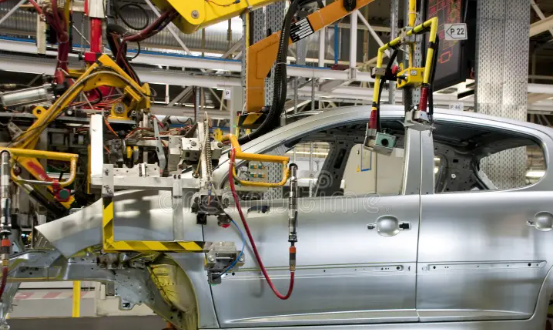

The welding wire market is buzzing with activity, and we’re seeing some clear trends shaping its future. Automation is a big one—robotic welding systems are taking over in aerospace and automotive plants, delivering pinpoint accuracy and faster production. This means our wires need to perform flawlessly in high-speed, automated setups, and we’re optimizing them for just that. Another trend is the push for lightweight materials, especially in automotive manufacturing, where electric vehicles (EVs) and hybrids demand aluminum and high-strength steel welds to cut weight without sacrificing strength.

Sustainability is also a hot topic. With stricter environmental regulations, we’re developing eco-friendly wires and fluxes that reduce emissions and waste during welding. The global welding consumables market is expected to grow at a steady 5.8% annually through 2030, driven by demand in aerospace, automotive, and infrastructure. The rise of EVs is a big factor—automakers need specialized wires to join lightweight alloys for battery housings and chassis. Meanwhile, aerospace is pushing for stronger, more heat-resistant welds to support next-gen aircraft designs.

We’re also seeing growth in additive manufacturing, where our wires are used in wire-arc additive processes to build complex parts layer by layer. This is a game-changer for prototyping and small-batch production in aerospace. Our R&D team is working hard to stay ahead, testing new alloy blends and welding techniques to meet these evolving needs.

In aerospace, our welding wires are critical for building safe, high-performance aircraft. Stainless steel and nickel alloy wires are used to join fuselage sections, engine components, and landing gear, where strength and corrosion resistance are non-negotiable. These welds need to withstand extreme stresses, from high-altitude cold to engine heat, and our wires deliver joints that last. Aluminum wires are also a big deal for aircraft panels, helping reduce weight to improve fuel efficiency and range—a must for modern planes.

The automotive sector is just as exciting. Our aluminum wires are perfect for welding lightweight body panels and frames, especially for EVs where every kilogram matters. Stainless steel wires are used for exhaust systems and structural components, providing corrosion resistance and durability. Mild steel wires come into play for heavier parts like chassis and suspension systems, offering strong, cost-effective welds. These applications help automakers build vehicles that are safer, more efficient, and longer-lasting, which is critical as the industry shifts toward sustainable mobility.

Beyond aerospace and automotive, our wires are making an impact in energy and infrastructure. In power generation, nickel alloy wires are used to weld turbine components that face extreme heat and corrosion. In construction, mild steel wires are a staple for joining structural beams and pipelines, ensuring buildings and infrastructure stand the test of time. Our ability to tailor wires for specific welding processes—like high-speed MIG for automotive or precision TIG for aerospace—means we’re meeting diverse needs across industries.

Parameter | Stainless Steel | Aluminum | Nickel Alloy | Mild Steel |

|---|---|---|---|---|

Melting Point (°C) | 1,400–1,500 | 660 | 1,320–1,450 | 1,500–1,600 |

Tensile Strength (MPa) | 500–700 | 200–400 | 600–800 | 400–550 |

Corrosion Resistance | Excellent | Very Good | Excellent | Moderate |

Weldability | Good (requires skill) | Good (clean surfaces needed) | Excellent | Excellent |

Typical Applications | Aerospace frames, exhaust systems | Automotive bodies, aircraft panels | Turbine components, chemical plants | Structural frames, pipelines |

Cost-Effectiveness | Moderate | High | Lower | High |

Wire Diameter Range (mm) | 0.8–2.4 | 0.8–2.0 | 1.0–2.4 | 0.6–2.4 |

Welding isn’t without its hurdles. Creating strong, defect-free welds in lightweight alloys can be tricky, especially for EVs and advanced aircraft. We’re tackling this by fine-tuning our wire compositions to improve weldability and reduce issues like porosity. Cost is another challenge—high-performance wires like nickel alloys are pricier, so we’re exploring ways to optimize alloys without compromising quality. Scaling up for large-scale production, like welding entire aircraft fuselages, also demands efficiency and consistency.

The opportunities, though, are massive. The EV boom is driving demand for aluminum and high-strength steel wires, and we’re ready to meet it with specialized solutions. Additive manufacturing is opening new doors, letting us use our wires in innovative ways to build complex parts. Plus, as industries push for greener processes, our eco-friendly wires and low-emission fluxes are gaining traction. We’re also leveraging automation, ensuring our wires perform seamlessly in robotic systems to boost productivity.

We’re pumped about what’s next. Our R&D team is testing new wire formulations, like advanced aluminum-nickel blends, to push the limits of strength and corrosion resistance. We’re also investing in smart welding technologies, like sensors that monitor weld quality in real time, to make manufacturing even more reliable. Collaborations with aerospace and automotive leaders are helping us tailor our wires to real-world challenges, from lightweight EV frames to heat-resistant jet engine parts.

In 2025, our welding wires are set to play a starring role in revolutionizing manufacturing. Whether it’s building the next generation of fuel-efficient planes or durable, eco-friendly cars, we’re committed to delivering solutions that drive innovation. By staying ahead of market trends and focusing on quality, we’re helping aerospace and automotive industries build a stronger, more sustainable future. Expect big things as we keep pushing the boundaries of what’s possible with welding.

1. What materials are used in our welding wires?

We primarily use stainless steel, aluminum, nickel alloys, and mild steel, chosen for their strength, corrosion resistance, and versatility.

2. Which industries benefit most from our welding wires?

Aerospace, automotive, construction, and energy sectors rely on our wires for strong, durable welds in critical applications.

3. How do our welding wires improve manufacturing processes?

They ensure high-strength, reliable joints that withstand stress, corrosion, and high temperatures, boosting component longevity and safety.

4. What are the latest trends in the welding wire market?

We’re seeing increased automation, demand for lightweight alloys, and a push for eco-friendly welding solutions in manufacturing.

5. Can our welding wires be customized for specific projects?

Yes, we offer tailored wire compositions, diameters, and flux types to meet unique requirements in aerospace and automotive applications.