Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Stainless Steel Welding Wire

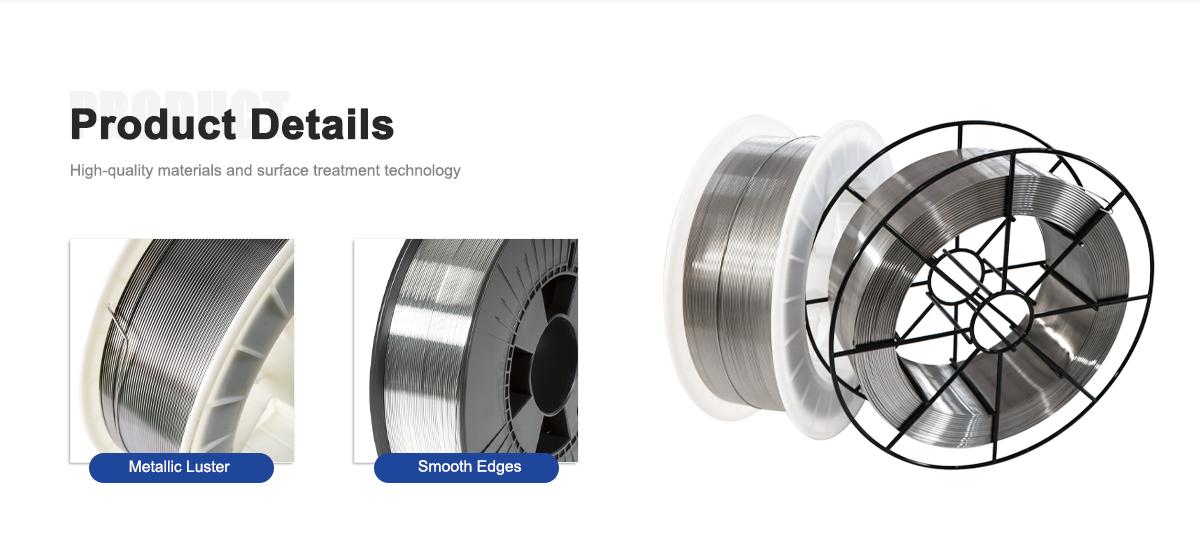

Product Details

Our ER316L MIG Welding Wire is a top performer for high-temperature chemical processing welds. With 18-20% chromium, 11-14% nickel, and 2-3% molybdenum, this low-carbon wire is built for MIG welding, delivering smooth arcs, minimal spatter, and clean weld beads. It’s perfect for welding 316L stainless steel, offering superior corrosion resistance and strength in harsh, high-heat environments. Whether you’re working on chemical tanks or processing equipment, our ER316L wire ensures welds that hold up and look great.

The Stainless Steel Welding Wire market is thriving, driven by demand in chemical processing, oil and gas, and pharmaceutical industries where corrosion resistance and heat tolerance are critical. 316L stainless steel is a go-to for its ability to withstand aggressive environments, making it ideal for high-temperature applications. Trends show a rise in automated MIG welding for faster production and a focus on sustainable materials to meet environmental standards. Our ER316L wire is designed to excel, offering reliable performance for both manual and robotic setups in a competitive market.

| AWS Classification | Applications |

| ERNiCr-3 | Used for welding 600, 601, and 800 alloys and dissimilar welding between stainless steel and carbon steel |

| ERNiCrFe-7 | Suitable for welding nickel-chromium-iron alloys under ASTM B163, B166, B167, and B168 standards |

| ERNiCrFe-6 | Designed for welding steel to nickel-chromium-iron alloys, as well as stainless steel to nickel-based alloys |

| ERNiCrCoMo-1 | Used for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERNiCrMo-3 | Suitable for nickel alloy, carbon steel, stainless steel, and low alloy steel welding, primarily used for 625, 601, 802 alloys, and 9% nickel alloys |

| ERNi-CI | Used for welding commercially pure nickel, malleable cast iron, and gray cast iron |

| ERCuNi | Suitable for welding 70/30, 80/20, and 90/10 copper-nickel alloys |

| ERNiCu-7 | Used for welding nickel-copper alloys such as B127, B163, B164, and B165 |

| ERNi-1 | Designed for welding pure nickel castings and forgings, including those under ASTM B160, B161, B162, and B163 standards |

| ERNiFeMn-CI | Suitable for welding nodular cast iron, ductile iron, malleable cast iron, and gray cast iron, as well as their dissimilar welding to stainless steel, carbon steel, low alloy steel, and various nickel alloys |

| ERNiCrMo-4 | Used for welding nickel-chromium-molybdenum alloys, or for welding nickel-chromium-molybdenum alloys to steel and other nickel-based alloys |

| ERNiCrMo-11 | uitable for self-welding nickel-chromium-molybdenum alloys, dissimilar welding with steel and other nickel alloys, and also for cladding applications |

| ERNiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-3 | Designed for welding nickel-chromium-molybdenum alloys, including 625, 800, 801, 825, and 600 |

| ENiCrFe-3 | Used for welding nickel-chromium-iron alloys and for dissimilar welding with carbon steel |

| ENiCrFe-2 | Suitable for welding austenitic steel, ferritic steel, and high-nickel alloys, also used for 9% nickel alloy welding |

| ENiCu-7 | Primarily used for welding nickel-copper alloys and their dissimilar welding with steel |

| ENiCrFe-7 | Ideal for welding 690 (UNS N06690) nickel-chromium-iron alloys |

| ENiCrMo-4 | Designed for C-276 alloy welding and most nickel-based alloys |

| ENiCrCoMo-1 | Suitable for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERCuNi | Used for welding forged or cast 70/30, 80/20, and 90/10 copper-nickel alloys |

| ENiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-11 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| Welding Wire Type | Density (g/cm³) | Melting Point (°C) | Electrical Conductivity (% IACS) | Coefficient of Thermal Expansion (10⁻⁶/°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Wire | 7.85 | 1450 | 8-10 | 11.8 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Wire | 7.9 | 1350-1450 | 2-5 | 16-17 | 550-650 | 300-400 | 30-40 |

| Aluminum Welding Wire | 2.7 | 600-660 | >60 | 23.1 | 150-200 | 75-100 | >20 |

| Nickel Alloy Welding Wire | 8.4 | 1350-1400 | 1-2 | 13.1 | 600-800 | 400-600 | 30-40 |

| Welding Rod Type | Coating | Electrical Resistivity (10⁻⁶ Ω·cm) | Hardness (HV) | Heat Resistance (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Rod | Acid coated, alkaline coated | 10-15 | 150-200 | < 450 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Rod | Acid coated, alkaline coated | 60-80 | 200-400 | < 800 | 550-750 | 350-450 | 25-35 |

| Cast Iron Welding Rod | Alkaline coated | 90-120 | 250-450 | 300-600 | 300-500 | 150-300 | 10-20 |

| Nickel Alloy Welding Rod | Alkaline coated | 80-100 | 200-300 | < 1200 | 700-900 | 450-650 | 20-35 |

For more other size details, pls directly contact us

ER316L MIG Welding Wire is a champ for tough jobs. It’s ideal for welding chemical processing equipment like reactors, tanks, and piping that face high temperatures and corrosive substances. In oil and gas, it’s used for pipelines and vessels exposed to harsh chemicals. It’s also perfect for pharmaceutical equipment, ensuring hygienic, corrosion-resistant welds. From power plants to marine applications, this wire delivers strong, durable joints that perform under extreme conditions.

Parameter | Our ER316L MIG Wire | Competitor’s Stainless Steel Wire |

|---|---|---|

Alloy Type | 18-20% Cr, 11-14% Ni, 2-3% Mo, low-carbon | Often less optimized Mo or higher carbon |

Corrosion Resistance | Superior, ideal for chemical and marine use | Moderate, less reliable in harsh environments |

High-Temperature Performance | Excellent, perfect for extreme heat applications | Limited, less suited for high temperatures |

Arc Stability | Smooth arc with minimal spatter | Inconsistent, prone to spatter |

Feedability | Outstanding, optimized for automated systems | May jam or feed inconsistently |

Weld Appearance | Clean, professional-grade beads | Uneven, may require rework |

Applications | Chemical processing, oil & gas, pharmaceutical | Limited to less demanding tasks |

Welding Compatibility | Works with standard MIG welders | May need specialized equipment |

About Us:

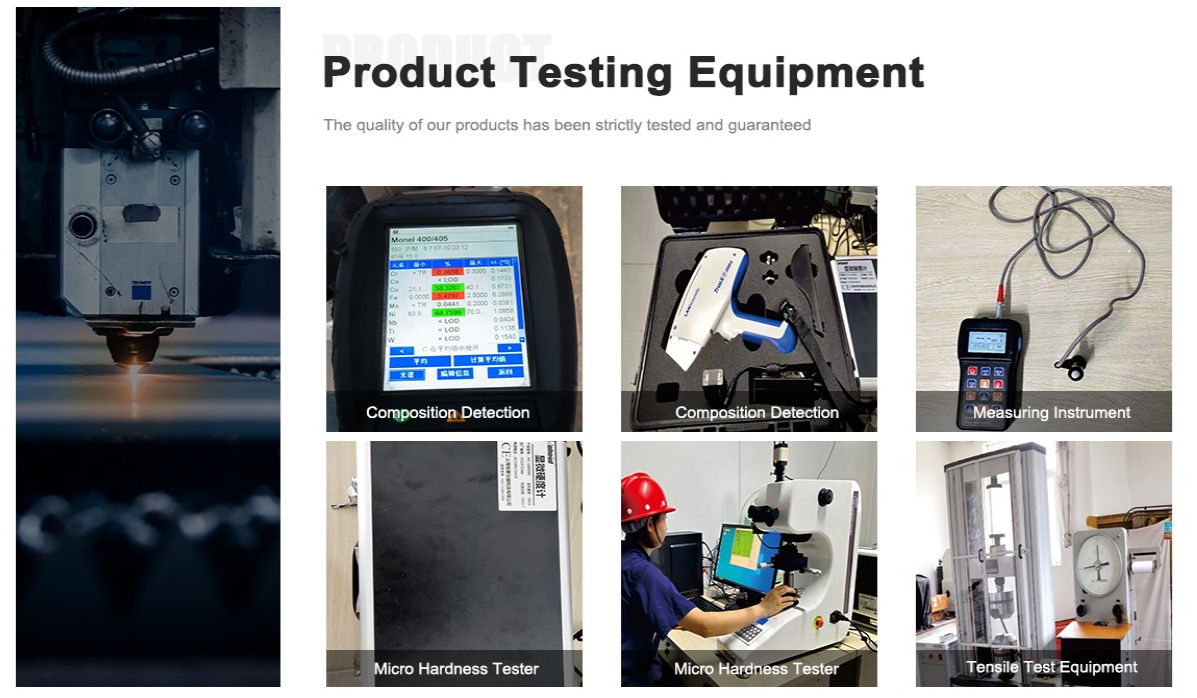

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is ER316L MIG Welding Wire used for?

It’s used for welding 316L stainless steel in chemical processing, oil and gas, and pharmaceutical applications.

Which industries rely on ER316L wire?

Chemical processing, oil and gas, pharmaceutical, and marine industries use it for high-temperature welds.

Is ER316L suitable for high-temperature environments?

Yes, its molybdenum content ensures excellent performance in high-heat conditions.

Can ER316L be used in automated welding systems?

Absolutely, its smooth feedability is perfect for robotic MIG welding.

How does ER316L perform in corrosive environments?

It offers superior corrosion resistance, ideal for chemical and marine settings.

Is ER316L compatible with standard MIG welders?

Yep, it works seamlessly with most MIG welding setups.

What’s the advantage of ER316L for chemical processing?

It delivers strong, corrosion-resistant welds with clean beads for high-temperature applications.

Can ER316L weld other stainless steel grades?

Yes, it’s versatile for welding 316, 316L, and similar austenitic stainless steels.