Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Welcome to Jiangsu DZX Factory.

Email:dlx@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Professional manufacturer of welding wires and spraying wires,over 22 years.

Contact:Jason

Whatsapp:+8619906119641

Email:dlx@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nickel Welding Wire

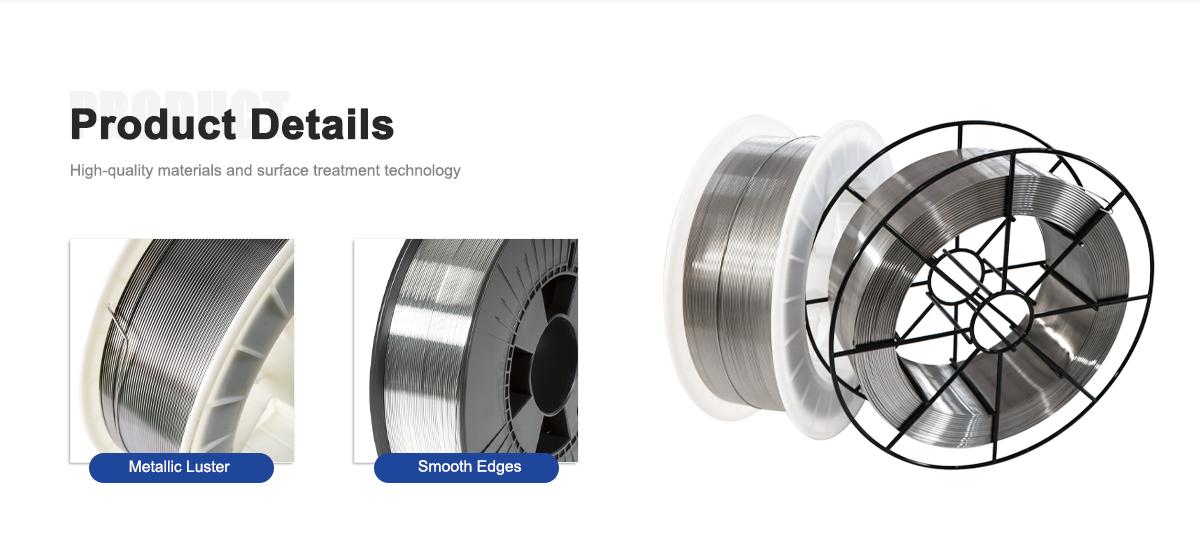

Product Details

Our ERNiCu-7 (Monel 400) Welding Wire is a rockstar for welders dealing with seawater and chemical equipment. This nickel-copper alloy wire, packing about 67% nickel and 30% copper, is designed to fight off corrosion in brutal environments like saltwater, acids, and alkalis. It’s the perfect fit for welding Monel 400 and similar nickel-copper alloys, delivering welds that are strong and built to last. With a tensile strength of around 80,000 psi and top-notch resistance to pitting and stress corrosion cracking, this wire ensures your equipment stays reliable. Whether you’re working on a desalination plant or a chemical tank, ERNiCu-7 delivers every time.

At DZX, we’ve engineered this wire for smooth welding. It flows cleanly in the weld pool, cuts down on defects like porosity, and performs like a dream in TIG and MIG setups. Available in diameters from 0.8mm to 1.6mm and packaged in spools or straight rods, it’s versatile for any job size. Built to AWS A5.14 standards, you can count on its quality for critical applications.

The nickel alloy welding wire market is thriving, driven by marine, chemical processing, and oil and gas industries. Corrosion-resistant materials are a hot commodity as companies aim to extend the life of equipment in harsh environments. Alloys like Monel 400 are in high demand for their ability to withstand seawater and chemical corrosion, making ERNiCu-7 a go-to for critical welds. The market’s growth is fueled by the need for durable materials in marine applications like desalination plants and offshore platforms, as well as chemical processing equipment facing aggressive acids.

Trends like automated welding and wire arc additive manufacturing are gaining momentum, requiring wires that deliver precise, clean welds. Stricter environmental and safety regulations are pushing for materials that reduce maintenance and downtime. Challenges like weld imperfections, such as cracking or porosity, make high-quality filler metals like ERNiCu-7 essential. The market is poised for growth as industries invest in reliable, corrosion-resistant solutions to keep operations running smoothly.

| AWS Classification | Applications |

| ERNiCr-3 | Used for welding 600, 601, and 800 alloys and dissimilar welding between stainless steel and carbon steel |

| ERNiCrFe-7 | Suitable for welding nickel-chromium-iron alloys under ASTM B163, B166, B167, and B168 standards |

| ERNiCrFe-6 | Designed for welding steel to nickel-chromium-iron alloys, as well as stainless steel to nickel-based alloys |

| ERNiCrCoMo-1 | Used for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERNiCrMo-3 | Suitable for nickel alloy, carbon steel, stainless steel, and low alloy steel welding, primarily used for 625, 601, 802 alloys, and 9% nickel alloys |

| ERNi-CI | Used for welding commercially pure nickel, malleable cast iron, and gray cast iron |

| ERCuNi | Suitable for welding 70/30, 80/20, and 90/10 copper-nickel alloys |

| ERNiCu-7 | Used for welding nickel-copper alloys such as B127, B163, B164, and B165 |

| ERNi-1 | Designed for welding pure nickel castings and forgings, including those under ASTM B160, B161, B162, and B163 standards |

| ERNiFeMn-CI | Suitable for welding nodular cast iron, ductile iron, malleable cast iron, and gray cast iron, as well as their dissimilar welding to stainless steel, carbon steel, low alloy steel, and various nickel alloys |

| ERNiCrMo-4 | Used for welding nickel-chromium-molybdenum alloys, or for welding nickel-chromium-molybdenum alloys to steel and other nickel-based alloys |

| ERNiCrMo-11 | uitable for self-welding nickel-chromium-molybdenum alloys, dissimilar welding with steel and other nickel alloys, and also for cladding applications |

| ERNiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-3 | Designed for welding nickel-chromium-molybdenum alloys, including 625, 800, 801, 825, and 600 |

| ENiCrFe-3 | Used for welding nickel-chromium-iron alloys and for dissimilar welding with carbon steel |

| ENiCrFe-2 | Suitable for welding austenitic steel, ferritic steel, and high-nickel alloys, also used for 9% nickel alloy welding |

| ENiCu-7 | Primarily used for welding nickel-copper alloys and their dissimilar welding with steel |

| ENiCrFe-7 | Ideal for welding 690 (UNS N06690) nickel-chromium-iron alloys |

| ENiCrMo-4 | Designed for C-276 alloy welding and most nickel-based alloys |

| ENiCrCoMo-1 | Suitable for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys |

| ERCuNi | Used for welding forged or cast 70/30, 80/20, and 90/10 copper-nickel alloys |

| ENiCrMo-13 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| ENiCrMo-11 | Used for welding low-carbon nickel-chromium-molybdenum alloys |

| Welding Wire Type | Density (g/cm³) | Melting Point (°C) | Electrical Conductivity (% IACS) | Coefficient of Thermal Expansion (10⁻⁶/°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Wire | 7.85 | 1450 | 8-10 | 11.8 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Wire | 7.9 | 1350-1450 | 2-5 | 16-17 | 550-650 | 300-400 | 30-40 |

| Aluminum Welding Wire | 2.7 | 600-660 | >60 | 23.1 | 150-200 | 75-100 | >20 |

| Nickel Alloy Welding Wire | 8.4 | 1350-1400 | 1-2 | 13.1 | 600-800 | 400-600 | 30-40 |

| Welding Rod Type | Coating | Electrical Resistivity (10⁻⁶ Ω·cm) | Hardness (HV) | Heat Resistance (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

| Carbon Steel Welding Rod | Acid coated, alkaline coated | 10-15 | 150-200 | < 450 | 400-550 | 300-400 | 20-25 |

| Stainless Steel Welding Rod | Acid coated, alkaline coated | 60-80 | 200-400 | < 800 | 550-750 | 350-450 | 25-35 |

| Cast Iron Welding Rod | Alkaline coated | 90-120 | 250-450 | 300-600 | 300-500 | 150-300 | 10-20 |

| Nickel Alloy Welding Rod | Alkaline coated | 80-100 | 200-300 | < 1200 | 700-900 | 450-650 | 20-35 |

For more other size details, pls directly contact us

ERNiCu-7 Welding Wire is a powerhouse for seawater and chemical equipment. In marine applications, it’s ideal for welding desalination plant components, ship fittings, and offshore platform parts exposed to saltwater. The chemical processing industry uses it for tanks, valves, and piping systems that handle acids, alkalis, and other corrosive substances. In oil and gas, it’s perfect for pipelines and subsea equipment facing harsh, corrosive conditions. It’s also a great choice for heat exchangers and pump components, where durability and corrosion resistance are critical.

This wire’s ability to resist pitting and stress corrosion cracking makes it a top pick for both new builds and repairs. Its clean weld appearance ensures equipment looks professional, while its versatility across TIG and MIG processes makes it suitable for a wide range of applications, from small fixes to large-scale projects.

|

Parameter |

ERNiCu-7 |

Other Nickel Alloy Welding Wire |

|---|---|---|

|

Nickel Content |

~67% for superior corrosion resistance |

Often lower, e.g., 50-60% |

|

Tensile Strength |

80,000 psi (as welded) |

Typically 70,000-90,000 psi |

|

Corrosion Resistance |

Outstanding, ideal for seawater and acids |

Moderate, less suited for harsh conditions |

|

High-Temperature Use |

Stable up to 1,000°F (538°C) |

Some handle higher temperatures |

|

Base Metal Compatibility |

Monel 400, similar nickel-copper alloys |

Broader but less optimized for Monel |

|

Weldability |

Smooth flow, low defect rate |

Varies, higher risk of imperfections |

|

Pitting Resistance |

Excellent, resists seawater pitting |

Often less effective in corrosive settings |

|

Applications |

Marine, chemical, oil and gas equipment |

General-purpose, less specialized |

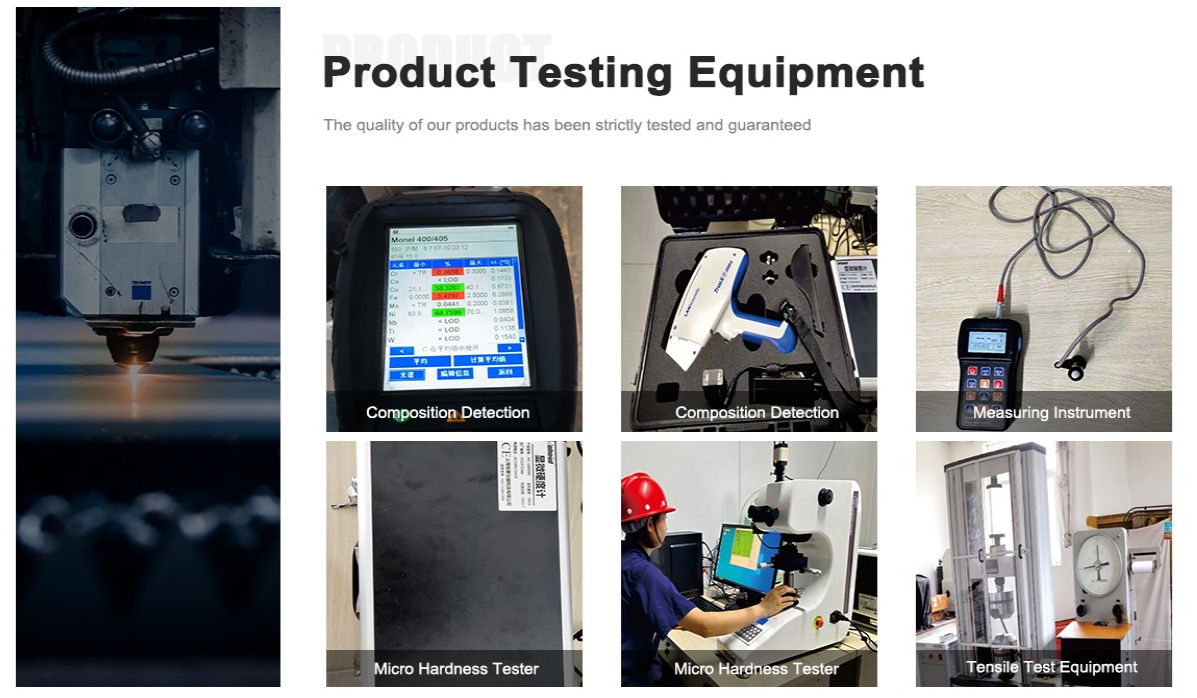

At DZX, we’re all about delivering quality you can trust. Our ERNiCu-7 Welding Wire is crafted with state-of-the-art manufacturing to ensure consistent performance. We meet AWS A5.14 standards, focusing on purity and precision to minimize weld imperfections like porosity or cracking. Our process eliminates issues like kinks or uneven feeding, so your welding is smooth and efficient, even on critical marine or chemical equipment.

We’re more than just a supplier. Our team provides expert support, helping you select the right wire diameter or optimize welding settings for your project. We offer flexible packaging—spools for continuous welding or straight rods for precision TIG work—to fit your needs perfectly. With our high production capacity, we deliver fast, even for large orders, without compromising quality.

Sustainability and efficiency are at the heart of what we do. ERNiCu-7’s excellent weldability reduces rework, saving you time and materials. We’ve optimized our supply chain to keep costs competitive while delivering a premium product. With DZX, you’re partnering with a company dedicated to your success, ensuring welds that hold up in the toughest seawater and chemical environments.

Our ERNiCu-7 Welding Wire is built for seawater and chemical equipment, delivering strong, corrosion-resistant welds that stand up to harsh conditions. From desalination plants to chemical tanks, it ensures durability with minimal imperfections. Its versatility and clean weld profile make it a top choice for critical applications. With DZX, you get a high-quality product backed by a team committed to helping you succeed. Choose ERNiCu-7 for welds that endure corrosion and keep your equipment running strong.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

Why is ERNiCu-7 great for seawater equipment?

Its high nickel and copper content offers excellent resistance to saltwater corrosion, ideal for marine applications.

What alloys can ERNiCu-7 weld?

It’s optimized for Monel 400 and similar nickel-copper alloys.

How strong are ERNiCu-7 welds?

They provide a tensile strength of around 80,000 psi, perfect for durable welds.

Can ERNiCu-7 handle chemical corrosion?

Yes, it resists acids, alkalis, and pitting in aggressive chemical environments.

What welding processes work with ERNiCu-7?

It’s designed for TIG welding but performs well in MIG setups for various projects.

Is ERNiCu-7 suitable for high-temperature applications?

It’s best for moderate temperatures, up to 1,000°F (538°C), due to its corrosion focus.

Which industries use ERNiCu-7?

Marine, chemical processing, and oil and gas sectors rely on it for corrosion-resistant welds.

How do I reduce weld imperfections with ERNiCu-7?

Clean the base metal, control heat input, and adjust current (100-250A) based on thickness to minimize porosity or cracking.